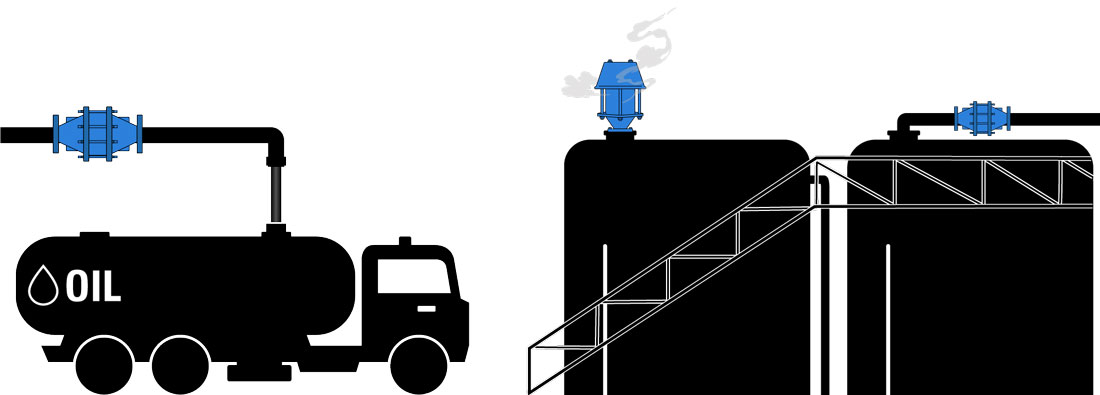

One of the greatest dangers in transporting and storing flammable liquids or gases is that the vapors could ignite, causing a fire or explosion.

A flame arrestor is a device that will permit gases or vapors to flow but prevent the transmission of a flame should an ignition take place.

In this article, we’re going to look at the different types of flame arrestors available to give you a general understanding of how they work and the benefits they offer.

Where are flame arrestors used?

Wherever a flammable gas or vapor is mixed with air, there is the potential for an explosion.

Accidental ignition of the flammable mixture will result in a flame that will travel through the unburnt mixture until the fuel is consumed by the reaction.

Applications for flame arrestors include:

- Gas disposal systems like flares

- Vapor recovery systems

- Atmospheric-pressure storage tanks

- Gas processing vessels

Several options of flame arrestors can protect your equipment from this flame transmission.

Deflagrations vs Detonations

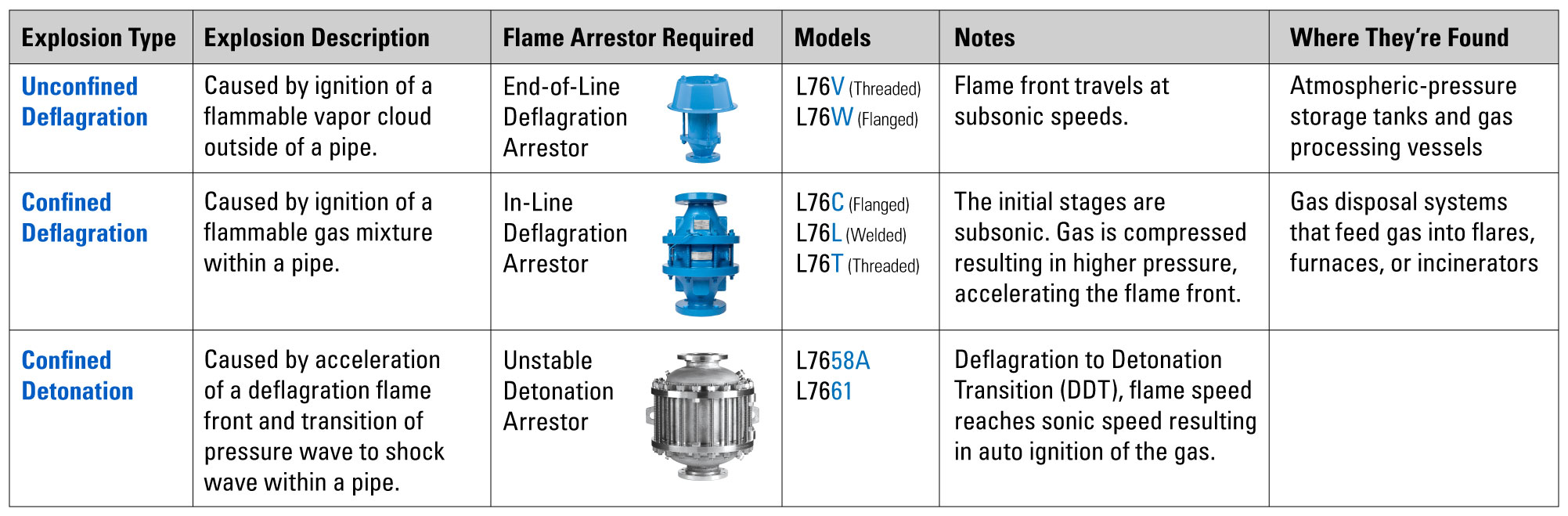

First, there are two explosive mechanisms to consider with flame arrestors: deflagrations and detonations.

Deflagrations

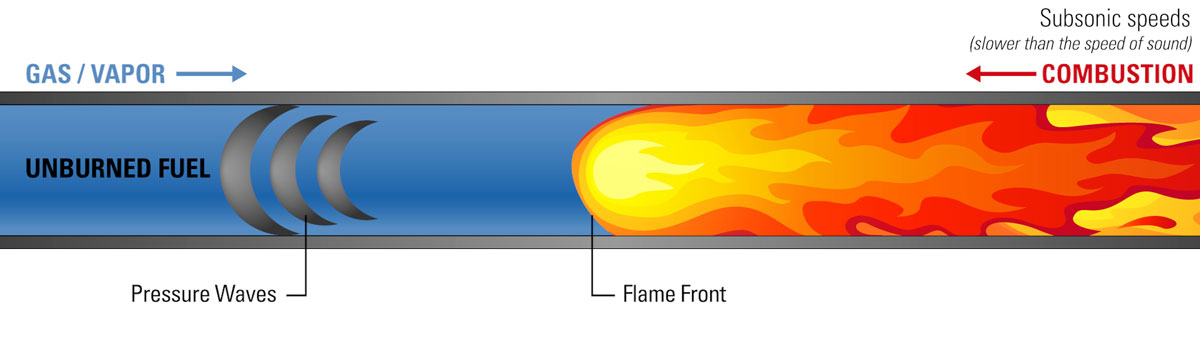

Deflagrations are flame fronts traveling at subsonic speeds. When the gas is ignited the flame begins to accelerate. This acceleration results in the build-up of a pressure wave ahead of the flame. This phase is known as deflagration.

Deflagration flame arrestors stop the initial phase of an explosion by blocking flames in a specific location to prevent fire from traveling through the pipeline.

Detonations

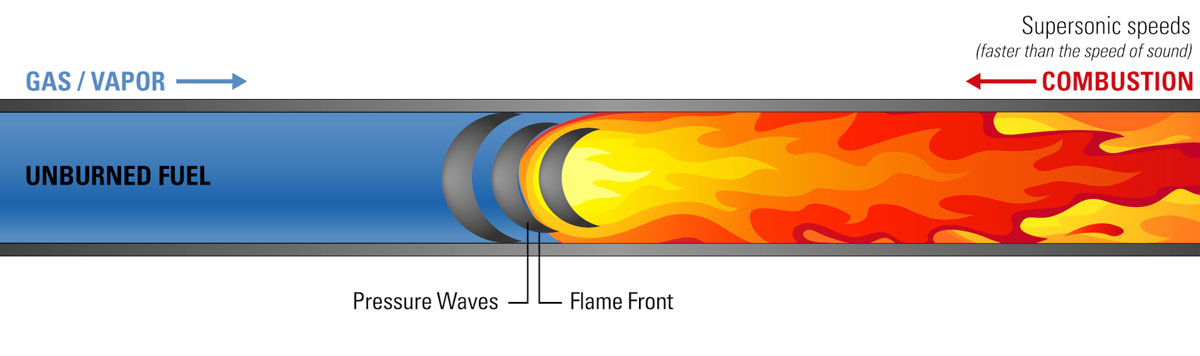

Detonations are flame fronts traveling at supersonic speeds. Once the shock wave reaches a pressure to auto-ignite the gas through which it is travelling, the flame front and shock wave couple together, forming an unstable detonation.

Detonation flame arrestors can withstand sudden explosions in pipelines and are more robust than deflagration arrestors. They protect against flame propagation through piping runs and vapor recovery systems while allowing for maximum flow efficiencies.

End-of-Line vs In-Line Flame Arrestors

For deflagrations, flame arrestors must be located at the open end of the pipe (end-of-line) or within a specified maximum distance from the ignition source (in-line).

End-of-Line flame arrestors are mounted on outlet flanges, and vent directly to the atmosphere. They are often used in oilfield storage tanks to prevent the tank from exploding if gas leaving the vent is struck by lightning.

In-Line flame arrestors may be installed at a specified maximum distance from the end of a section of open vent piping. They are often used in vapor recovery systems and equipment that collect flammable gases.

3 Types of Flame Arrestors

There are three types of LaMOT flame arrestors with various options in each category.

- End-of-Line Deflagration Arrestors are used where potential ignition sources are outside the system.

- In-Line Deflagration Arrestors confine the propagating flame.

- In-Line Unstable Detonation Arrestors are used in areas where the potential ignition sources are located far from the system.

Maintenance

Flame arrestors do not require a power source, have no moving parts, and many only require occasional cleaning or component replacement for maintenance.

All LaMOT flame arrestors can be inspected and cleaned if needed to prevent clogging, which can be noted by an increase in pressure drop. If there is an event and a flame front has been allowed to touch the flame bank, the flame bank must be replaced.

Typically, there is no visual indication externally that a flame has successfully been arrested. Because of this, regular cleaning and inspection of the internal flame bank is strongly recommended.

__

Each LaMOT product is tested and serialized to ensure high quality and traceability.

Reach out to your local Kimray representative today to explore what LaMOT products can do for your operation.