High Pressure Control Valves are used by upstream energy producers around the globe to control processes like separation and pressure reduction.

They can also be combined with other components to create pressure packages for regulation control.

Rather than ordering multiple components, connectors and tubing to assemble, producers can order application-specific valve packages, which include all the necessary accessories, pre-assembled.

In this video, we look at what producers find so useful about these valve packages and explore a few of the most popular and versatile product options.

Types of High Pressure Control Valve Packages

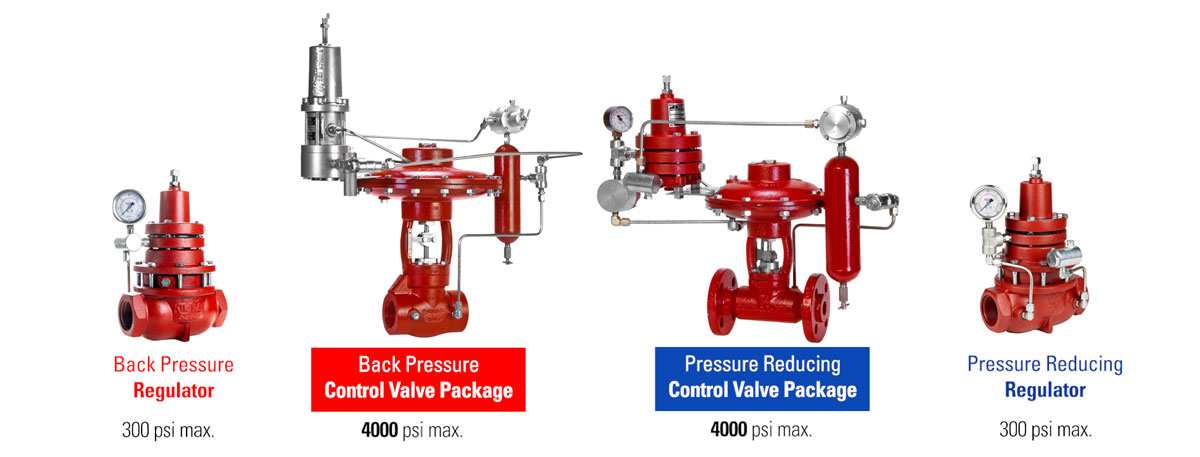

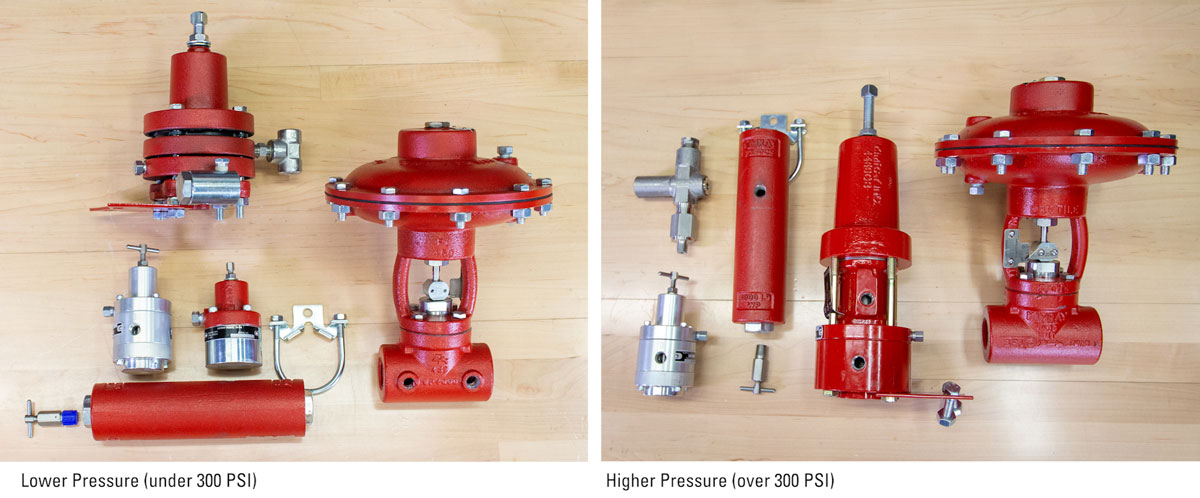

Kimray High Pressure Control Valve packages perform the same functions as Back Pressure and Pressure Reducing Regulators, but at higher working pressures—from 300 PSI to 4000 PSI, depending on the model.

Back Pressure Regulation

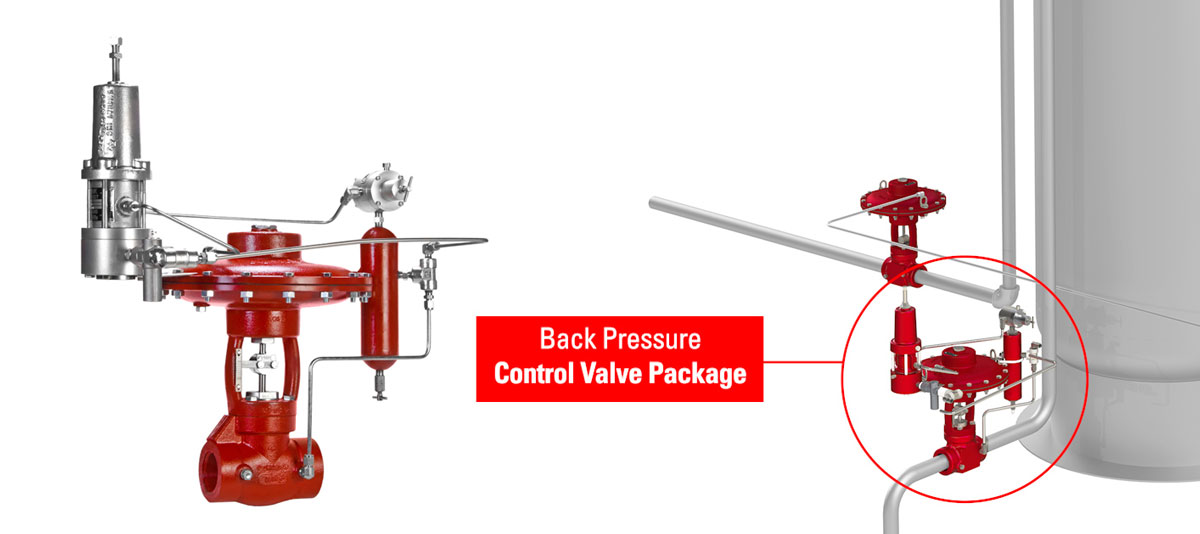

A High Pressure Back Pressure Package will hold a pressure set point on a vessel and aid the moving of the resources from one process to another. Without this pressure being held on the vessel, the liquids can’t be forced out of the vessel.

Pressure Reducing Regulation

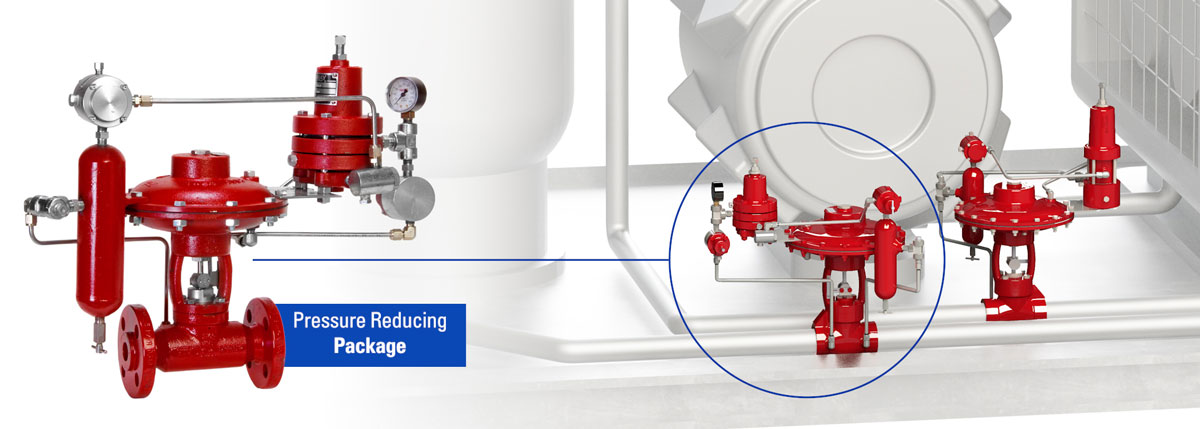

A High Pressure Pressure Reducing Package will hold a consistent set point downstream of the valve on high pressure flow lines.

Low Pressure Applications

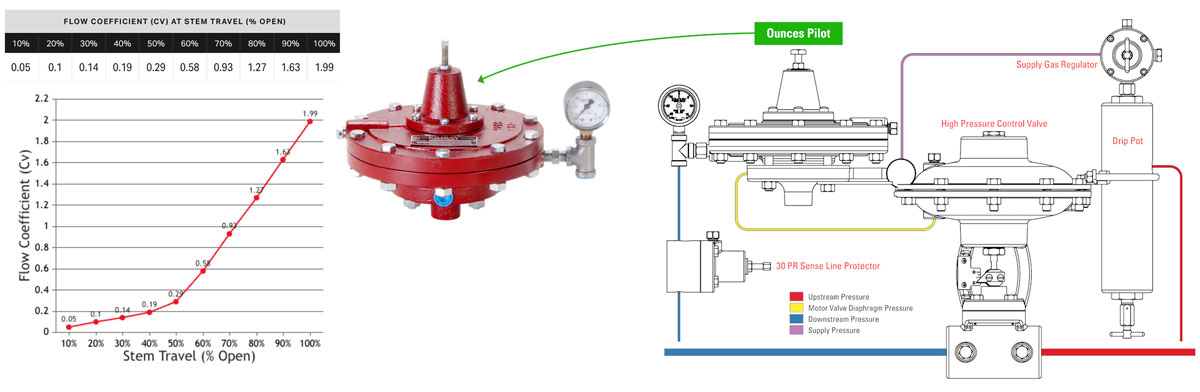

A High Pressure Control Valve package can also be used in a low pressure application. For example, if the Cv requirement of the application is lower than achievable with an integrated regulator, a package with an ounces pilot and small trim can be used.

What Is Included in a High Pressure Control Valve Package?

When you purchase a High Pressure Control Valve to use in either a back pressure or pressure reducing application, you need several additional components to make that valve function. Producers can order application-specific valve packages rather than ordering multiple parts to assemble themselves.

When you order from Kimray, we’ll help you spec your package, and it’ll be delivered fully assembled and ready to install. We strategically build these packages with the components closer together, facing the front of the valve and on the upstream side. This way they’re all accessible to the user, with less tubing used.

However, if you already have components or just need to swap out something to function for a different application, the parts are available individually and can easily be assembled with common tools and various tubing connectors.

We have also have step-by-step videos available for how to assemble High Pressure Control Valve Packages.

Now let’s go over the key components that will be needed for almost all valve packages.

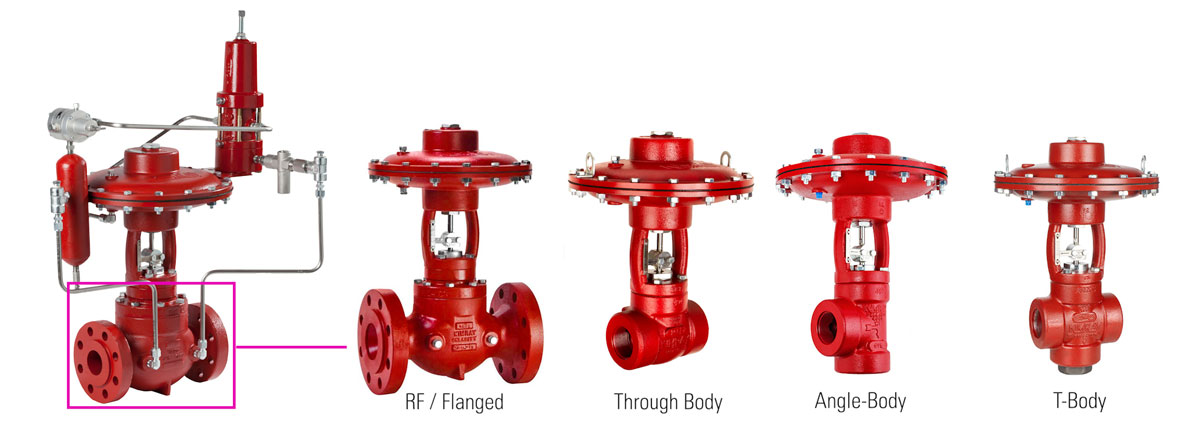

Valve Body

The first item is the High Pressure Control Valve body which comes in a variety of end connection sizes and types, all rated for pressure over 500 PSI.

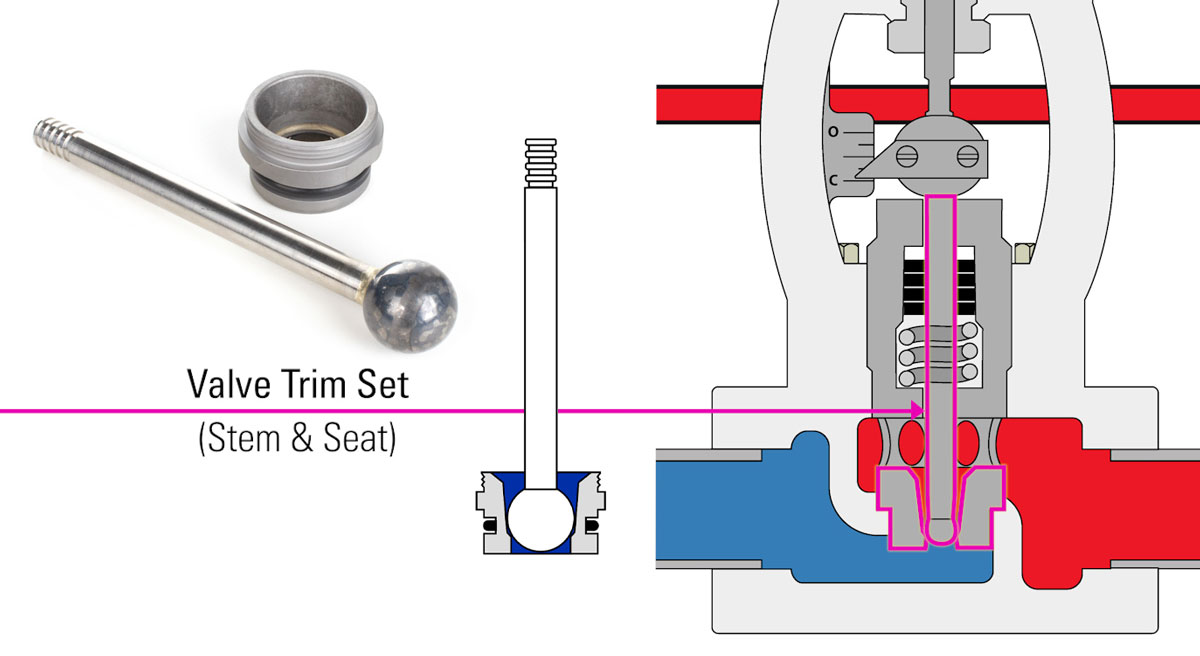

Valve bodies for control valve packages come standard with equal percentage trim. Various trim sizes and material options are available depending on your specific production conditions and all are easily replaceable for regular maintenance.

Pilot

%20and%20High%20Pressure%20(Bellows).jpg)

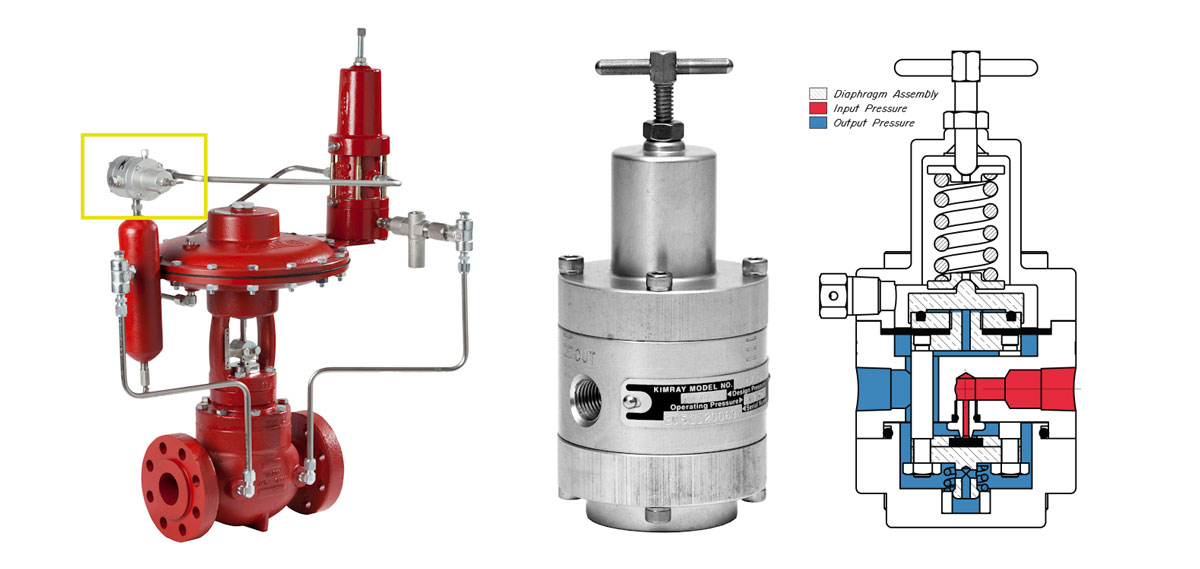

The Pilot tells the valve what to do. There are two main options:

- Low Pressure, or Diaphragm Controlled

- High Pressure or Bellows Controlled

The Bellows Controlled Pilot also allows for a package to control liquid pressure in high pressure conditions.

All pressure pilots on a valve package can optionally operate with zero emissions with no conversion or additional parts by using compressed air rather than supply gas from your production vessel.

Supply Gas Regulator (SGR)

Supply Gas Regulators reduce unregulated pressure to supply the pilot with constant reduced pressure.

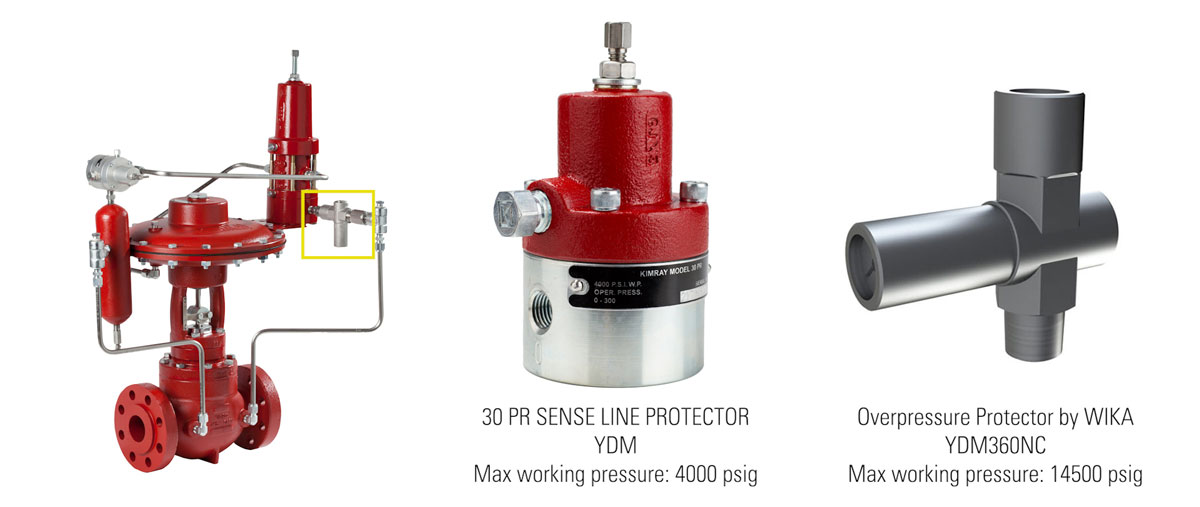

Sense Line Protector

Sense Line Protectors protect the pilot from over pressurization by blocking the supply pressure when it exceeds the adjustable limit.

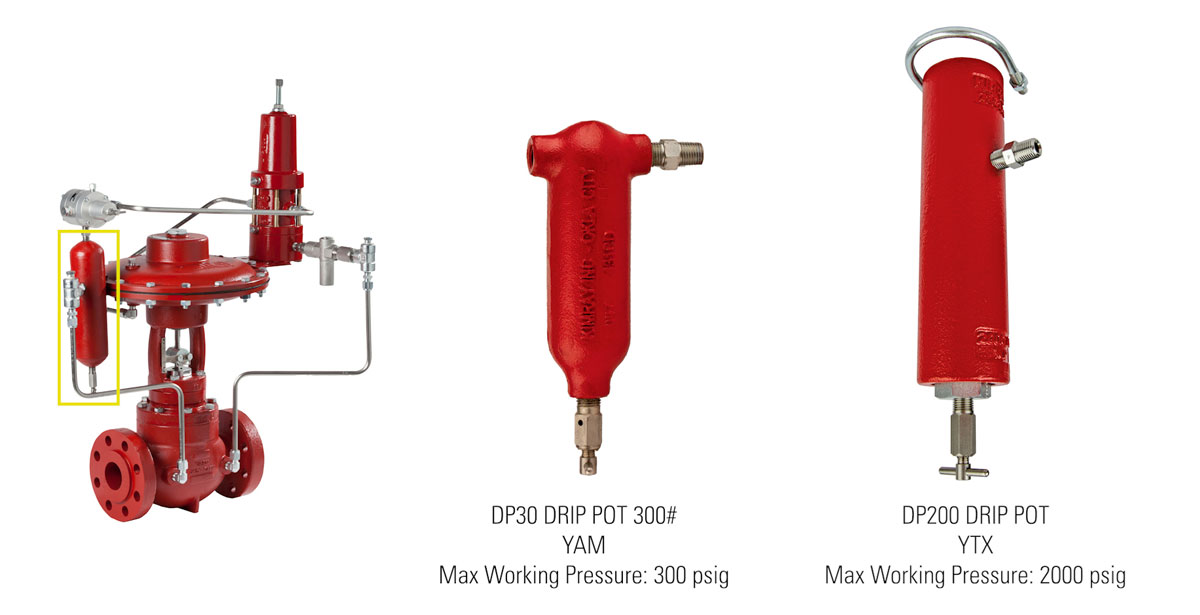

Drip Pot

The Drip Pot removes moisture from natural gas or compressed air before it flows into instrumentation where dry gas or air is required.

High Pressure Control Valve Package Maintenance

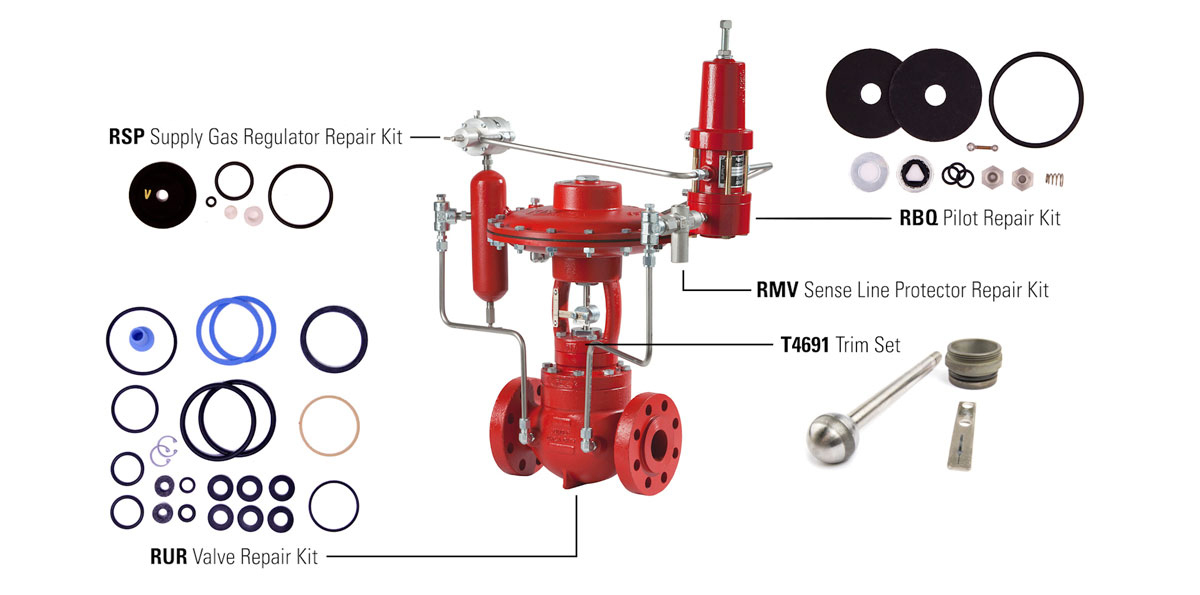

Operators can install product repair kits, which are available for most components on the package. Establishing a consistent valve maintenance routine of examining and replacing key components is a cost-effective way to keep them running longer.

To save time on this process, Kimray offers Field Services that can perform maintenance and repairs on-location.

Certifications

Manufactured and assembled in the USA, our High Pressure Control Valve Packages are certified for use in North and South America, and most areas around the world.