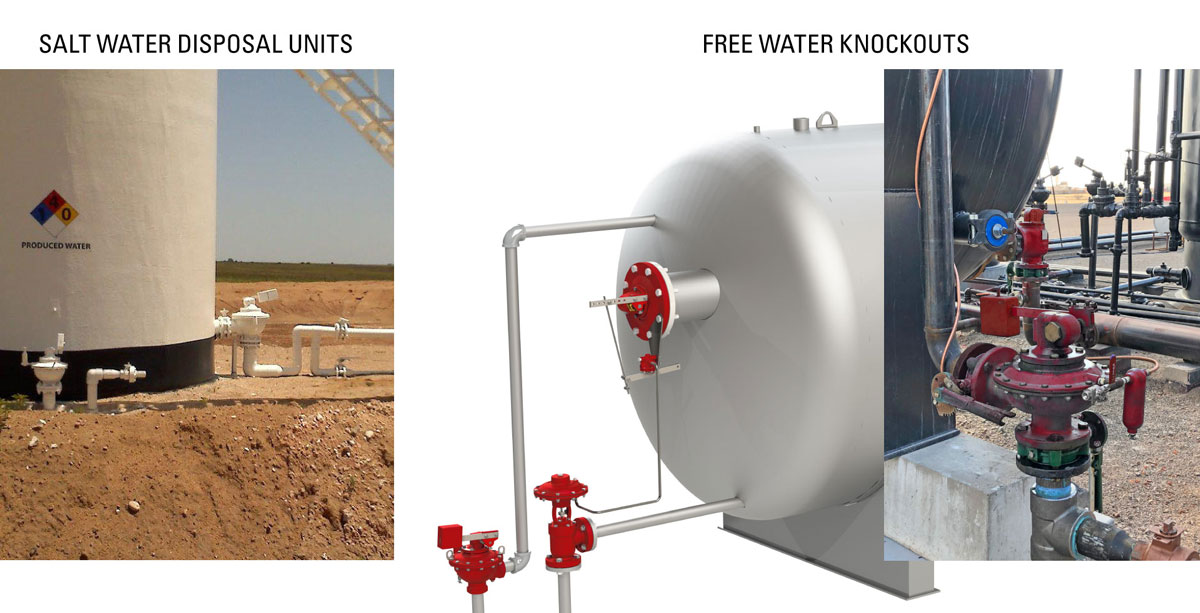

A Weight Operated Liquid Dump Valve is commonly used on production vessels like heater treaters for both the oil dump and water dump lines.

How a Weight Operated Liquid Dump Valve Works

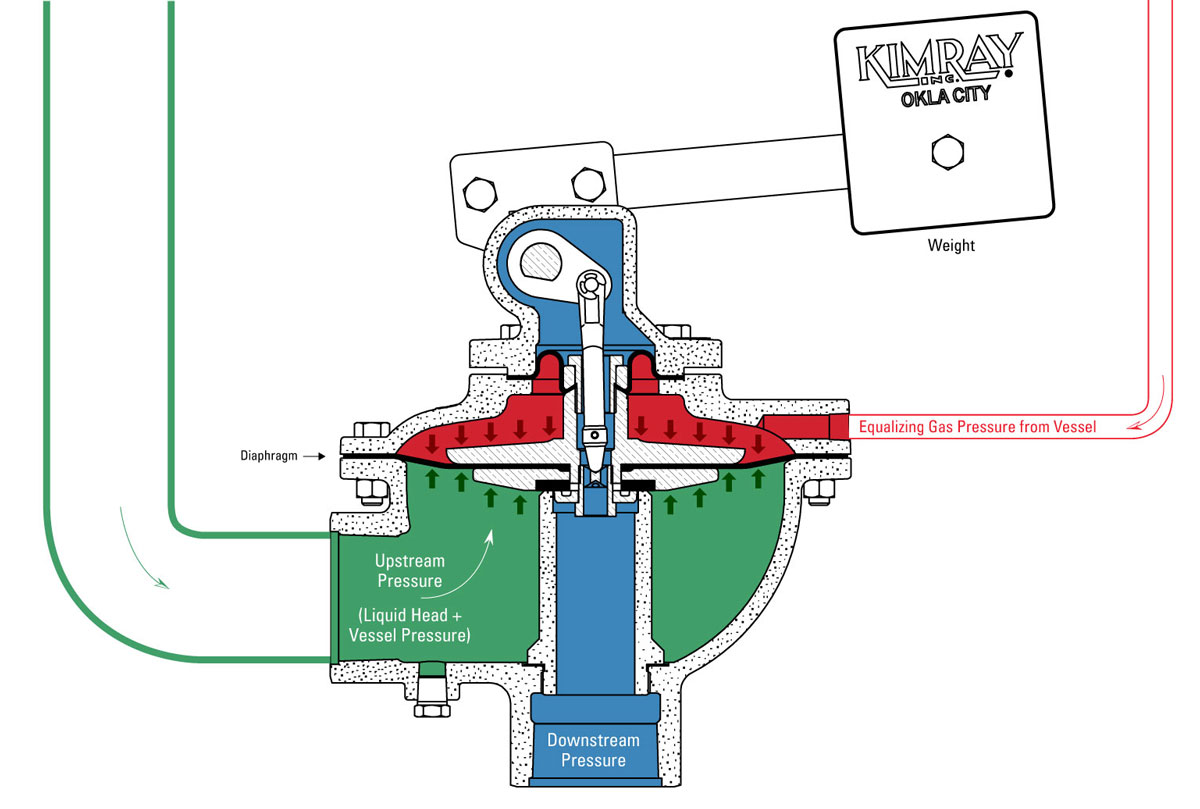

The Weight Operated Liquid Dump Valve uses a weight on the arm. Upstream pressure and the liquid head height push up on the main diaphragm inside of the valve. That works against the weight that's on the arm.

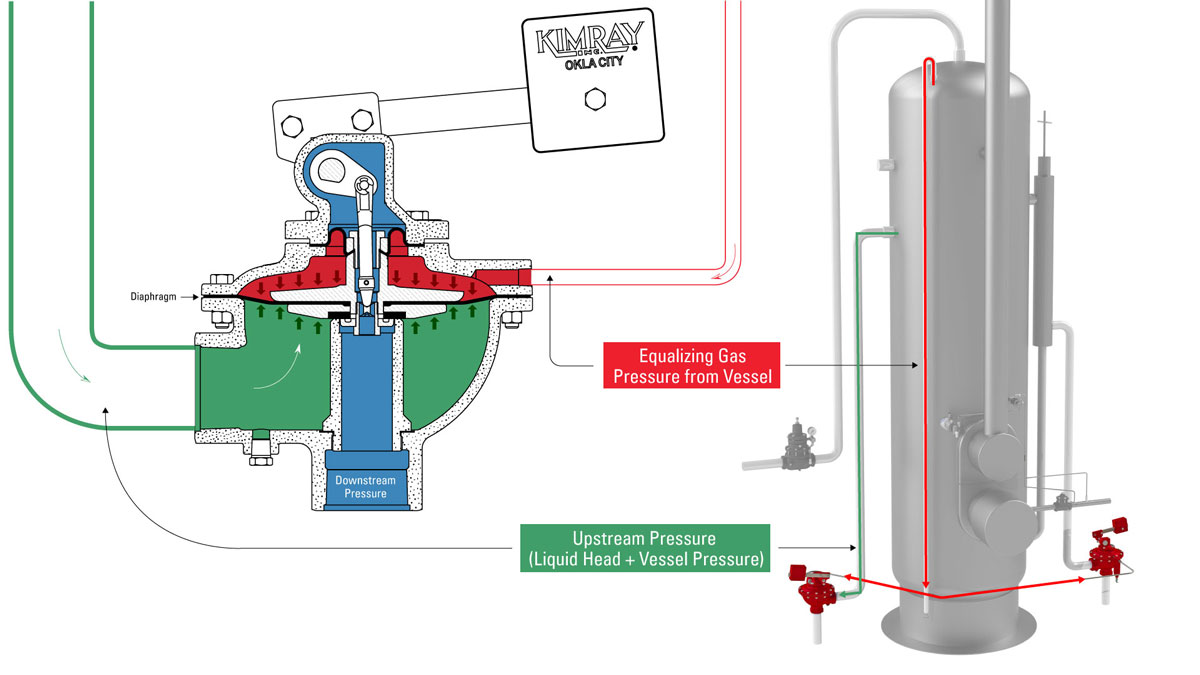

This is a balanced valve, which means the downstream pressure is balanced on the underneath side of the seat as well as on top of the balancing diaphragm.

One of the reasons this valve works so well in saltwater disposal applications is that a vacuum is pulling down on the seat, and it's also pulling up on the balancing diaphragm. This "balanced valve" means it doesn't matter whether you have positive pressure or negative pressure on the downstream side, it's still going to function correctly.

For this valve to operate only off the liquid head height, you have to balance the vessel pressure above and below the diaphragm. That's why there is an equalizing port.

Lever Bars, Weights, and Liquid Head Height

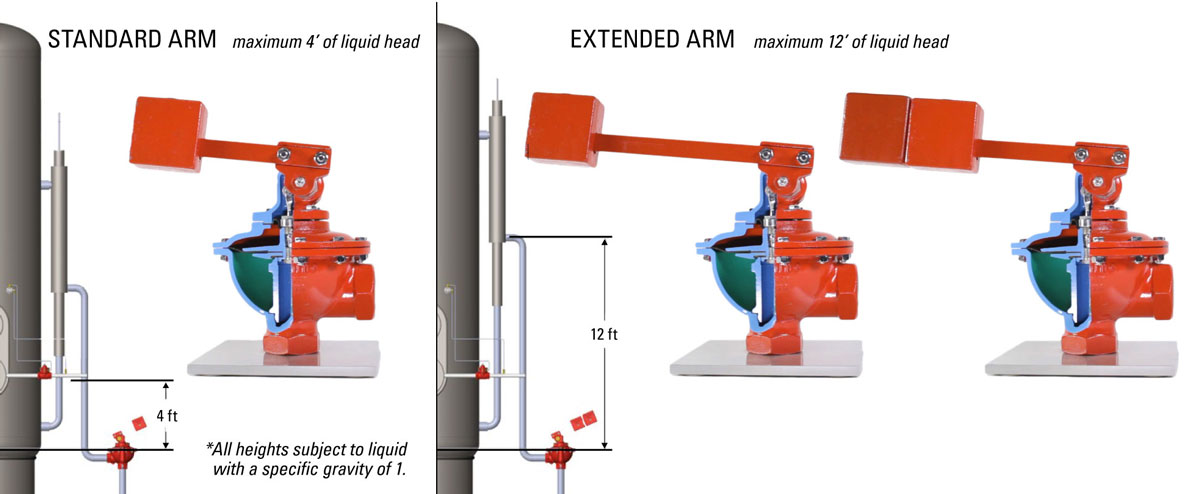

The position you have the weight on the arm lever bars determines what height of liquid you're holding inside of your vessel or the downcomer. As that liquid head builds, that pressure, plus the operating pressure of the vessel, open the valve.

You can put multiple weights on these valves and also extend the length of the arm to increase the maximum liquid head height that you can hold. With a single weight in our standard arm, you can hold up to 4 feet. With a double weight and an extended arm, you can hold up to 12 feet.

Adjustable Packing

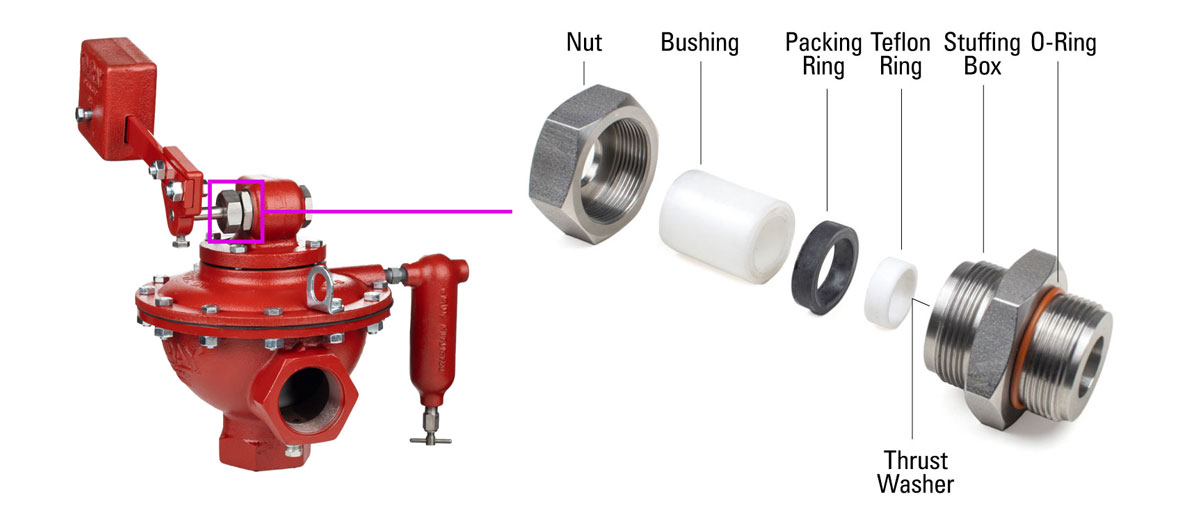

This valve has an adjustable packing much like some of our other liquid dump valves. As the packing begins to wear or leak under normal use, you can tighten the packing to stop those leaks and continue operating the valve without having to completely replace the packing.

However, you don't want to over tighten the packing, because that can restrict the movement of the valve and keep it from operating as it should.

The newer designs have new parts that we have put inside the valve, like the new shaft and the new hubs, to take out a lot of the play.

Manual Operation

Another good feature of the Weight Operated Liquid Dump Valve is that you can manually open and close it if you're wanting to test its function or how it's sealing.

To do this, move the arm on the external of the valve so you can get it to open and close, and you can just test the function of the whole system without having to manipulate anything else except the valve arm.

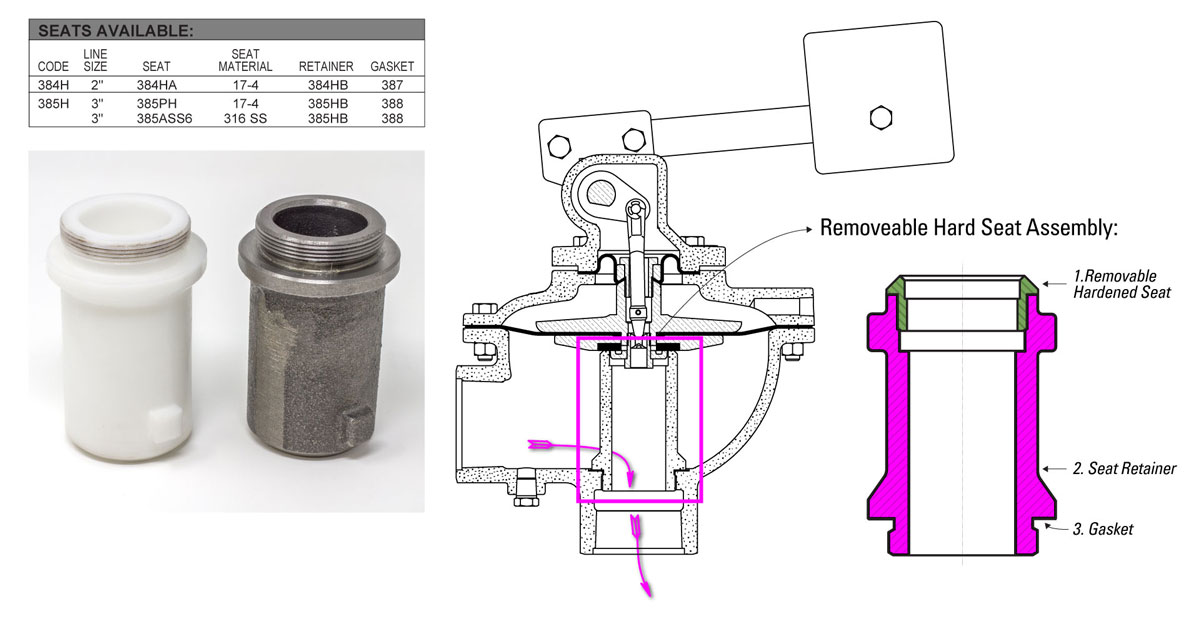

Material Options

Depending on the application you're using it in, we have different internal components such as a steel seat or a Delrin seat. In saltwater applications, we suggest going with stainless steel parts and for corrosive applications using Delrin.

In high temperature applications, if fluid goes over 180° the Delrin begins to deform. As long as your temperatures are below that, the Delrin will help mitigate corrosion from the saltwater.

We also offer different elastomer types. If you're running into issues with the valve packing or diaphragms failing, you can switch the elastomer type to fit your application.

You can also get these valves coated to help prevent corrosion.

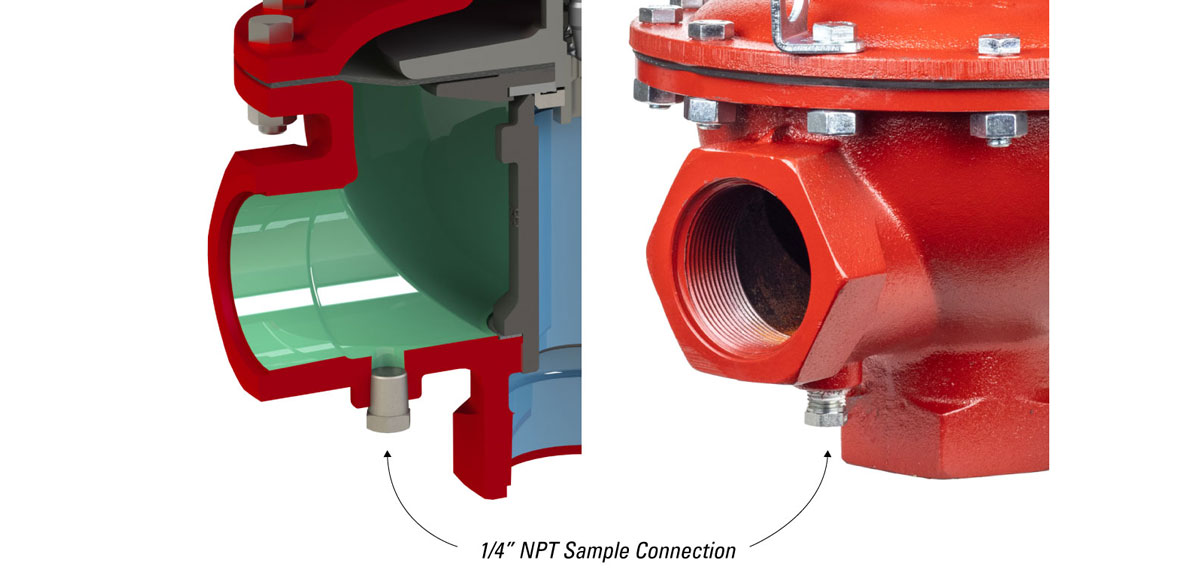

One pain point is at the sample connection. This is where you can pull samples from the upstream side of the valve to check BS&W levels and the concentration of the water to make sure it's getting the proper separation. A lot of salt can accumulate there, which can lead to corrosion on that port. Coatings can help mitigate this.

Troubleshooting the Gas Equalizing Line

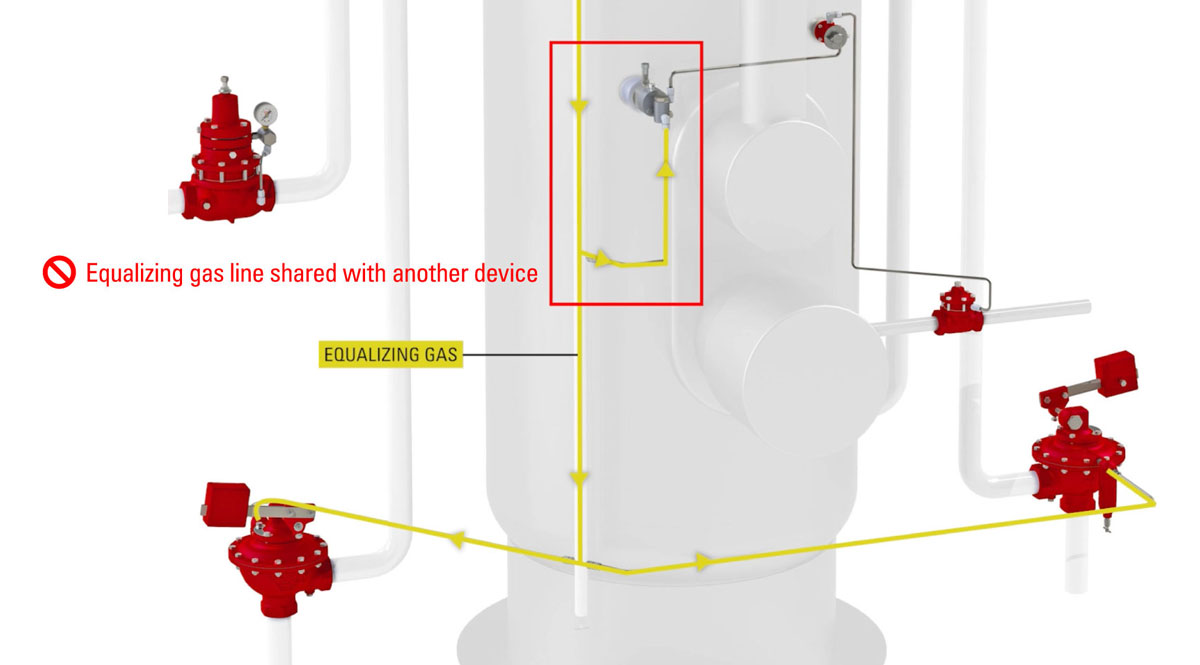

The step that is most commonly done incorrect is the gas equalizing line set up.

For this valve to operate correctly, the vessel pressure needs to be balanced above and below the main diaphragm in the valve. The most ideal setup is with a dedicated line from the top of the vessel.

The equalizing line should not be shared with your burner supply line or another line because as that burner kicks on, it's going to be drawing pressure away.

This means there will be a difference between the pressure that's on the upstream side of the valve and then that gas equalizing line going to the top of the diaphragm. When that happens, you'll get the valve oscillating open and closed really quickly. It won't be able to hold a consistent level in the downcomer or inside of the vessel.

You want a dedicated gas equalizing line coming from the top of the heater treater or vessel you're using this on.

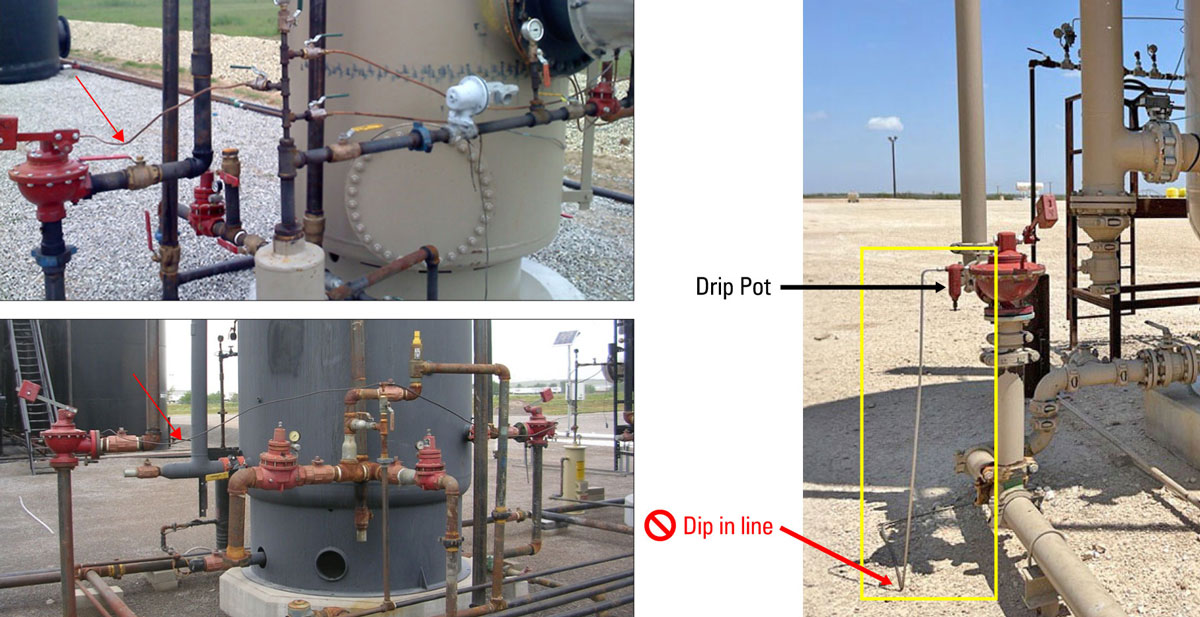

You also want to avoid any tubing dips where liquids might be able to collect.

You can see examples in the photos below of pulling a gas equalizing line from the same line that the burner is taking its fuel supply from. The line is stepped down from a 1" to 1/2" and then even further down to 1/4" tubing.

That's a sure way of restricting that gas flow. The pressure that the top of the valve is getting is going to be different from the pressure that's underneath or the vessel pressure. And that's when you'll start having operational issues.

Make sure that your lines are run straight with no low spots and that you are getting the gas equalizing line from a spot that's going to have the exact same pressure as the vessel pressure.

Troubleshooting an Oversized Valve

Another common issue is that the Dump Valve is oversized for the amount of production going through the vessel.

Operators often size it for initial production, but as that rapidly decreases, the valve becomes oversized.

An oversized valve will be opening and closing quite a bit. It won't stay open and its dump cycle won't be very long.

Ideally you want the valve to be throttling, so it has a longer dump cycle before then it closes. If you see a lot of "chattering," that's either the valve being oversized or it's unbalanced like we saw with the equalizing line issue.