The Kimray Energy Exchange Glycol Pump is the heart of any natural gas dehydration system.

In this video, Will shows answers 3 common questions we receive about the pump.

Question 1: Why Do Glycol Pumps Lose Prime?

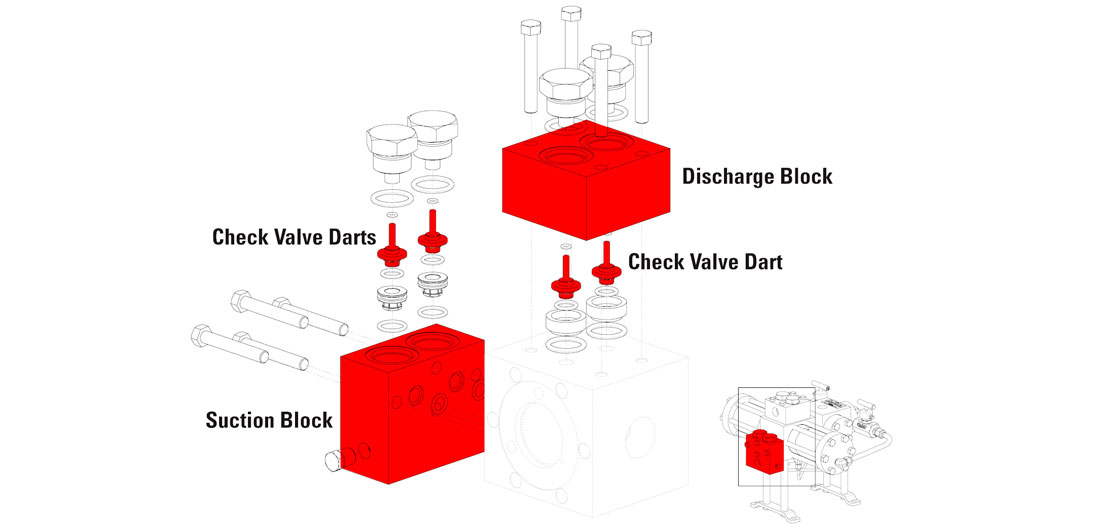

A pump has two sides—suction and discharge.

When it’s primed, it will be full of liquid and will achieve the correct pressures upstream and downstream.

When your suction side doesn’t have access to liquid, it’s just trying to pump air. This means you have lost prime.

There are a couple reasons it has lost prime:

Reason 1: Debris

If debris has gotten into the darts or suction line of the pump, it can cause a blockage, not allowing enough liquid to get into the pump.

Your first step to address this is to remove the darts to check them for debris. If there is debris, use brake cleaner to clean them.

While this may get your pump working, you will need to address the root cause, so it doesn’t happen again. To do this, we recommend upgrading your filtration.

Reason 2: Gelled Glycol

Another reason may be gelled glycol. In colder climates, glycol can gel inside the contact tower, which will prevent it from coming back to the pump.

- There are different places in the dehy system where you can take glycol samples to see if it has gelled. It would be a thick, viscous consistency.

- If this is the case, you may need to increase the temperature in the contact tower through the heat exchange. You want the glycol to be no more than 20°F higher than your gas temperature.

Question 2: Why Has My Pump Stalled?

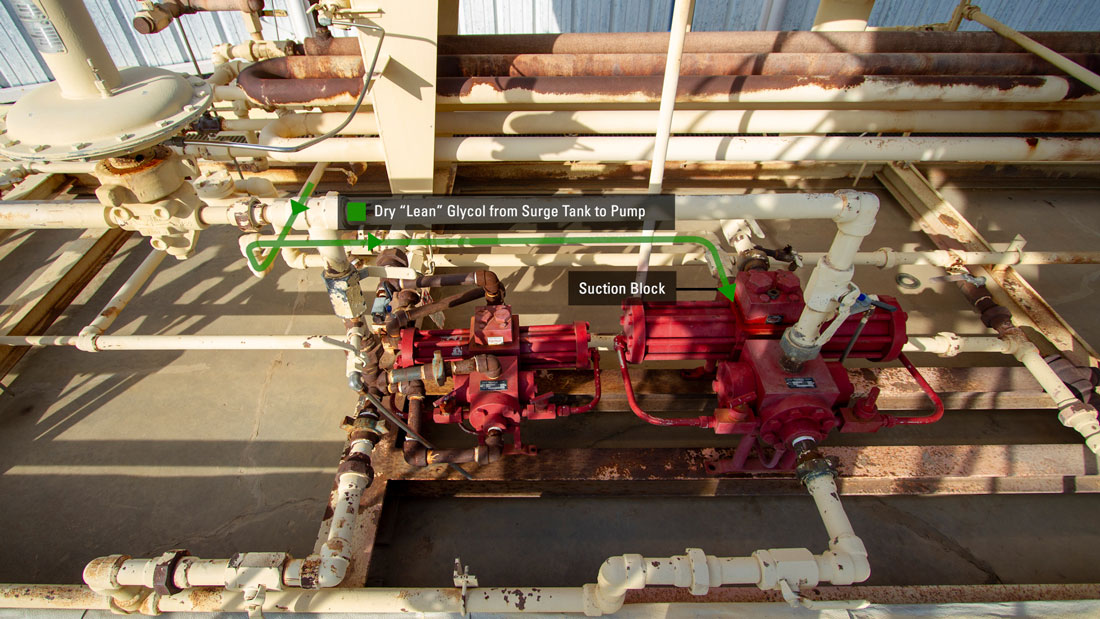

If your pump has stalled, the first thing to check is if the line on the low suction side is clogged from salt or other buildup. There should be a filter between the surge tank and the pump that may also get clogged.

When there is blockage, you can’t get glycol to the low suction side of the pump, which will cause it to stall.

Question 3: How Can I Make Proper Glycol Pump Adjustments for Flow Rate?

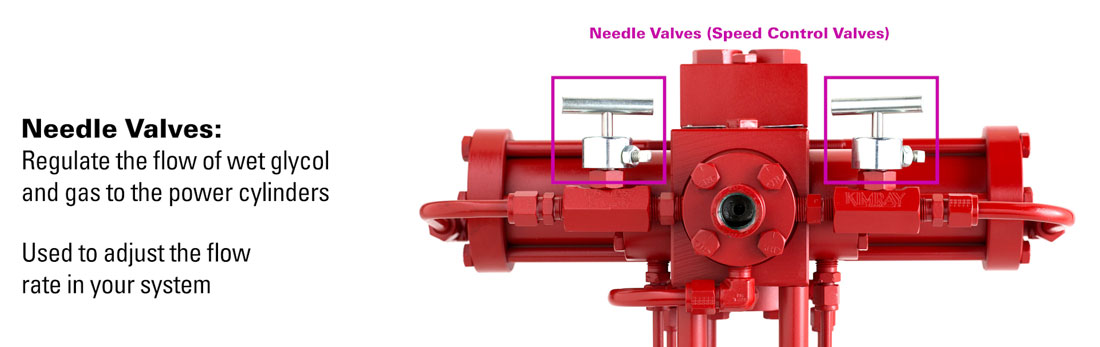

Needle valves, also called “speed control valves,” regulate the flow of wet glycol and gas to the power cylinders. They're used to adjust the flow rate in your system.

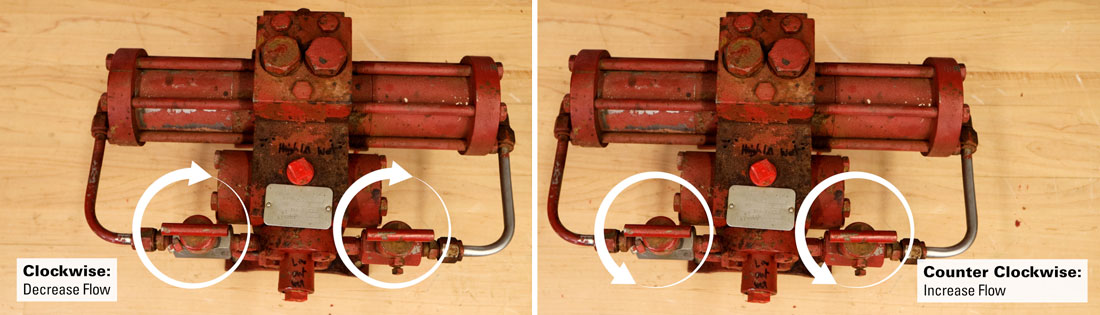

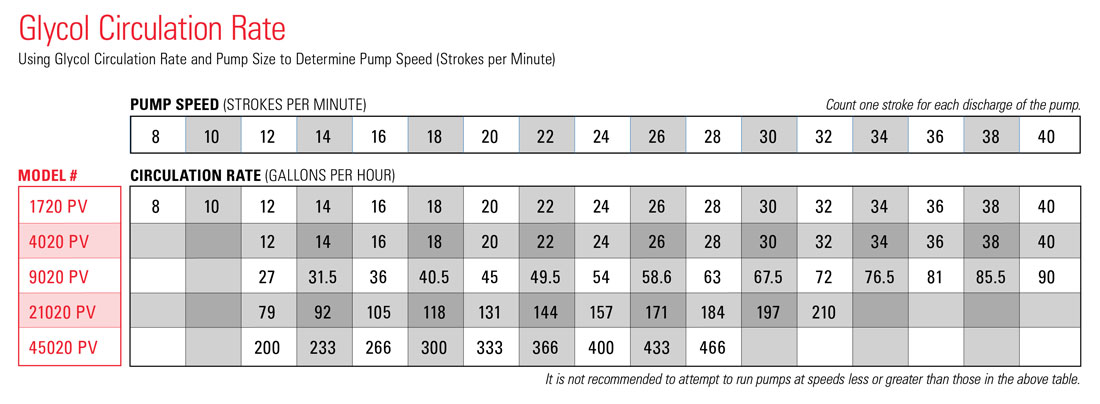

Turning them clockwise will decrease the flow; turning them counterclockwise will increase flow. Start small — a half turn in either direction. Then count your strokes-per-minute based on your size pump to know what your flow rate should be.

You can find this chart on the Technical Specifications for the glycol pump.

The most important thing to remember is to adjust your needle valves evenly. If you adjust one half a turn clockwise, you’ll need to do the same on the other to prevent imbalances.