Why is the Valve Seat Material Important?

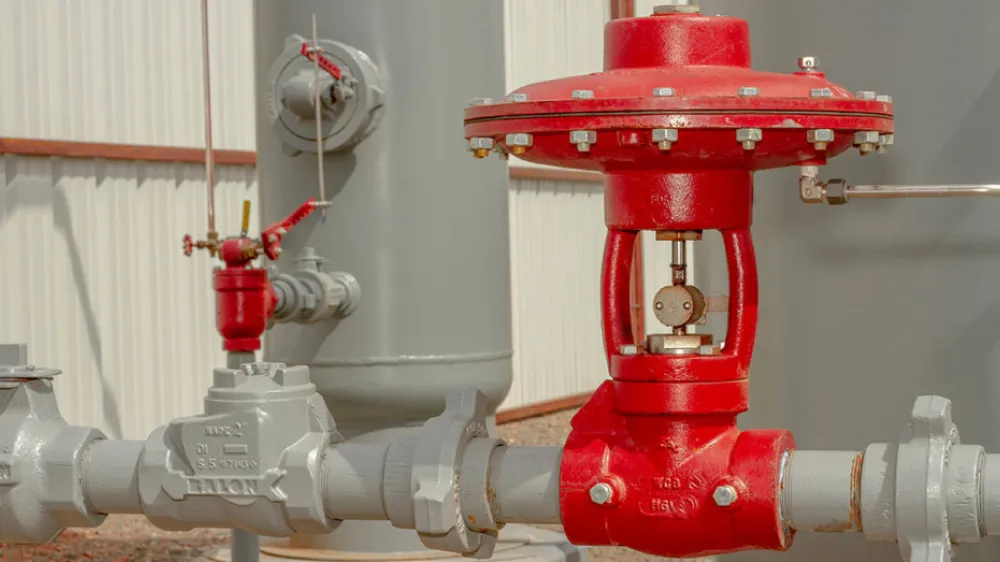

In a High Pressure Control Valve, the valve seat is the part inside of the valve against which the valve plug closes to seal off and shut the valve.

Long-lasting performance of this critical part is highly dependent on the valve seat material. Different conditions of your production fluid will dictate which type of material is best for your valve seat.

During the product selection process, the following variables should be considered:

- Pressure

- Temperature

- Flow rate

- Composition of the production fluid or gas

What is the Best Valve Seat Material for your Conditions?

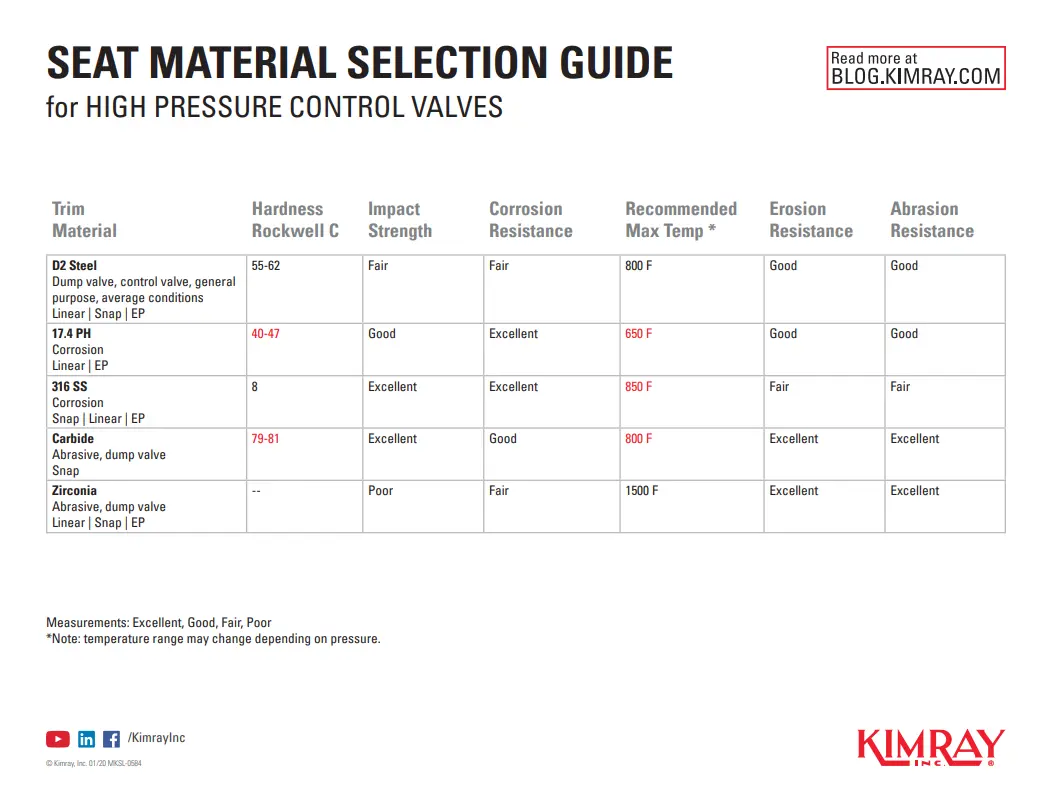

To help producers identify which seat materials would be best for their operation, we have created the Guide to Valve Seat Materials.

This guide features a matrix of various conditions and indicates which seat material is best for those conditions.

For example, if you want to control the liquid level in a separator and your production fluid has abrasives like sand, your best option for the dump valve may be our High Pressure Control Valve with a carbide or zirconia seat.

If you production fluid is high in H2S, which is a very corrosive element, you may want to specify a 316SS seat for your High Pressure Control Valve.

To speak with an expert about which seat material is best for your operation, contact your local Kimray store or authorized distributor.