PROBLEM

An oil and gas producer in North Dakota was looking for a solution to optimize production in highly erosive conditions. His application of valves was resulting in wash out issues due to the nature of the production fluid. There were two areas on the line causing issues:

- In the Oil Dump Line, pressure drops were causing salt to build up so quickly repairs were needed after just a few days of operation

- In the Water Dump Line, sand was causing erosion of production equipment

Kimray visited the site and discussed proper sizing, materials and flow path, taking note of the particular application and conditions.

SOLUTION

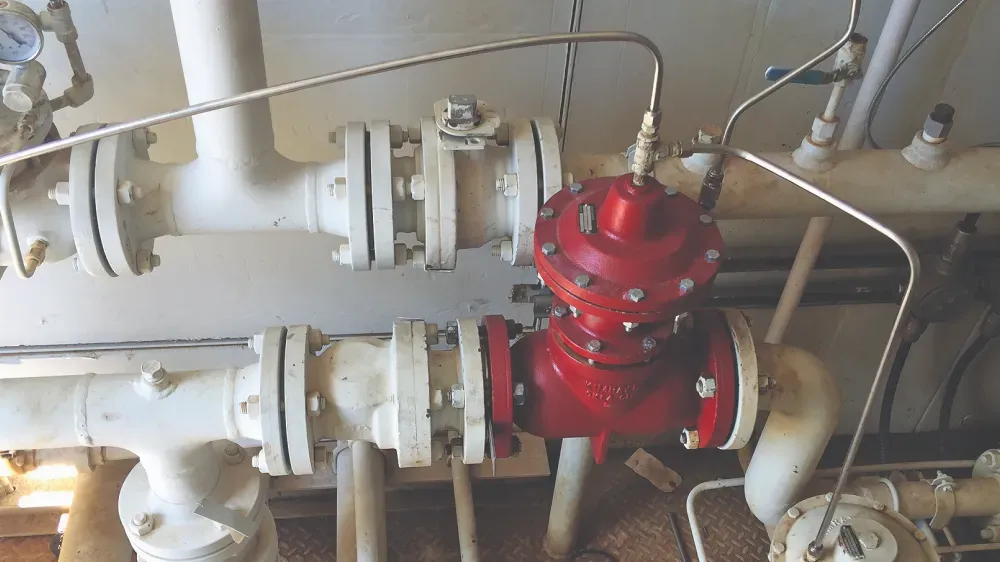

After some experimentation, Kimray installed a Lever Operated Piston Balanced Throttling piston into their Pneumatically Operated Valve, ground off the arrow and re-stamped the body. The goal was to offer a severe service pneumatic version that flowed backwards. This solution would remove the inner valve from the erosive service and prolong the valves’ life. Two valves with this set up were sent the producer for testing.

Test Valve 1

- Service: Oil Dump Line

- Purpose: Limit salt build up due to pressure drop through valve

- Date Installed: March 19, 2016

- Oil Temp: 93 F

- Separator Pressure: 50 PSI

- Average Oil Flow Rate: 100 BOPD

- Original Valve: 3” Diaphragm Balanced Pressure Open Dump Valve; Snap Operation

- Original Dump Valve Life (before salting off): 3-4 days

- Test Dump Valve Life: 11 weeks

Test Valve 2

- Service: Water Dump Line

- Purpose: Installed in the water dump line to provide better sand handling and less erosion. Installed in series with an orifice plate to lower the flow rate with the orifice to lower the fluid velocity through the valve.

- Date Installed: 5/28/16

- Separator Temperature: 116 F

- Separator Pressure: 82 PSI

- Avg Water Flow Rate: 350-400 BWPD

- Original Valve: 3” Diaphragm Balanced Pressure Open Dump Valve; Snap Operation

- Original Dump Valve Life (before eroding): 1 week

- Test Dump Valve Life: Going on 6 weeks without issue

RESULTS

The first test valve was installed on one of the saltiest oil wells on the oil dump line. The producer had battled salt build up in their oil dump valves due to the pressure drop across the valve. As shown in the summary on the right, the first valve lasted almost 10 weeks longer than the old style of oil dump valve. The producer also began periodically flushing the dump valves with fresh water at a rate of 1x a week to help keep the salt from building up.

The second test valve was installed on one of the sandiest wells on the water dump line. Dump valves have many design considerations, including making sure they are sized big enough to allow fluid to drain out of the vessel at an acceptable rate, yet not so oversized that they limit the blowby rate through the valve (should it fail open). In addition to these factors, it should also be able to withstand some sand erosion.

The second valve was placed upstream of a newly installed orifice plate. The purpose of the plate would be to limit flow rate and blowby of the dump system with a better (and cheaper) way to be replaced should it erode. This allowed the producer to oversize the dump valve (new valve had a full port 3”) to lower the flow rate and thus velocity through the valve body. As shown in the summary on the right, the second valve has lasted over five weeks longer than the original so far.