PROBLEM

One the biggest producers in Vaca Muerta was relying on pneumatic valves in their gas lift operation. They were using natural gas to actuate, leading to inefficiencies and environmental concerns due to gas

consumption.

The producer sought to modernize their system by automating valve operations to eliminate gas usage and enable remote monitoring and control. However, the aging pneumatic valves were incompatible with automation upgrades, necessitating a complete replacement.

Production Details

- Production Type: Gas Lift

- Gas Flow Rate: 6000 to 35000 Sm3/day

- Solids in Fluid: low

- Corrosiveness: low

- Upstream Pressure: 85 kg/cm2 (approximately 1209 psi)

- Downstream Pressure: 50 kg/cm2 (approximately 711 psi)

SOLUTION

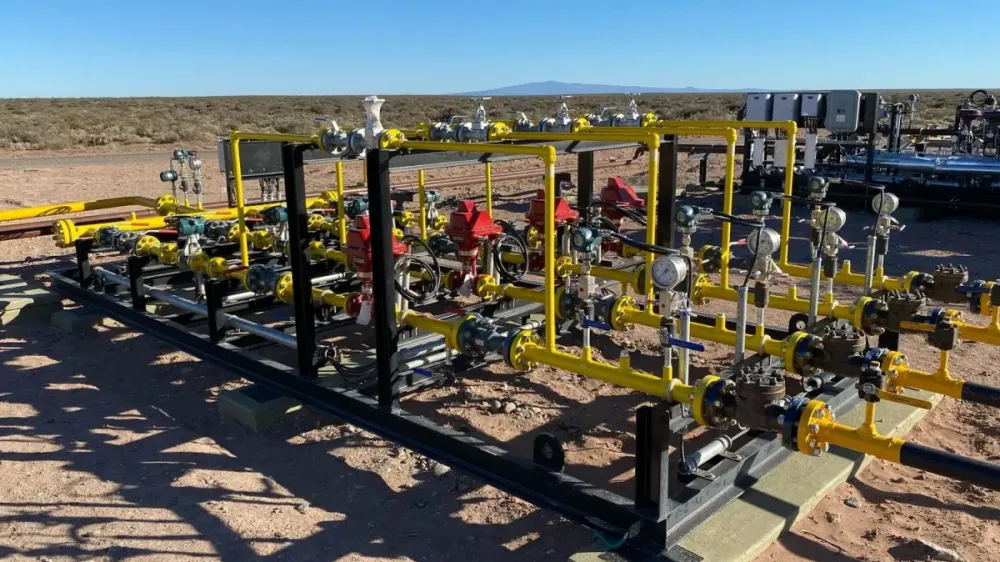

In April 2024, the operator replaced the outdated pneumatic valves with Kimray valves equipped with electric actuators.

These valves feature Modbus communication and 4-20 mA signal capabilities, allowing for remote monitoring and control without the need for pneumatic gas supply.

The electric actuators provided precise control, reduced environmental impact by eliminating gas consumption, and enabled integration with the client’s existing control systems for real-time data access.

Date of Installation: April 2024

Sizes Installed: 1” Kimray Valves with Electric Actuators

RESULTS

The producer reported four ways the new solution improved their gas lift system:

Longer Life

Initial data suggests a projected lifespan increased compared to pneumatic valves, based on reduced wear from gas-free operation and Kimray’s valve construction materials (long-term data still under evaluation).

Decreased Maintenance Times

The electric actuators require less frequent servicing and can be diagnosed remotely via Modbus

Reduced Environmental Impact

By eliminating the need for natural gas to operate the valves, the client reduced operational costs and environmental impact, aligning with stricter emissions regulations.

Remote Monitoring

The Modbus and 4-20 mA capabilities allowed operators to monitor valve performance in real time from a centralized control room, reducing the need for on-site interventions.