What is the Sand Problem in Oil and Gas?

Sand is a big challenge for oil and gas producers. After it's sent downhole to frack wells, it returns to the surface during flowback and production, where it can severely damage your equipment.

Along with piping and fittings, dump valves are the main pieces of equipment exposed to sand. Since they take the brunt of the impact from the sand, they are the main failure points for oil and gas producers.

Control Valve Erosion from Sand

During both flowback and normal production, frack sand is present in fluid coming from the well.

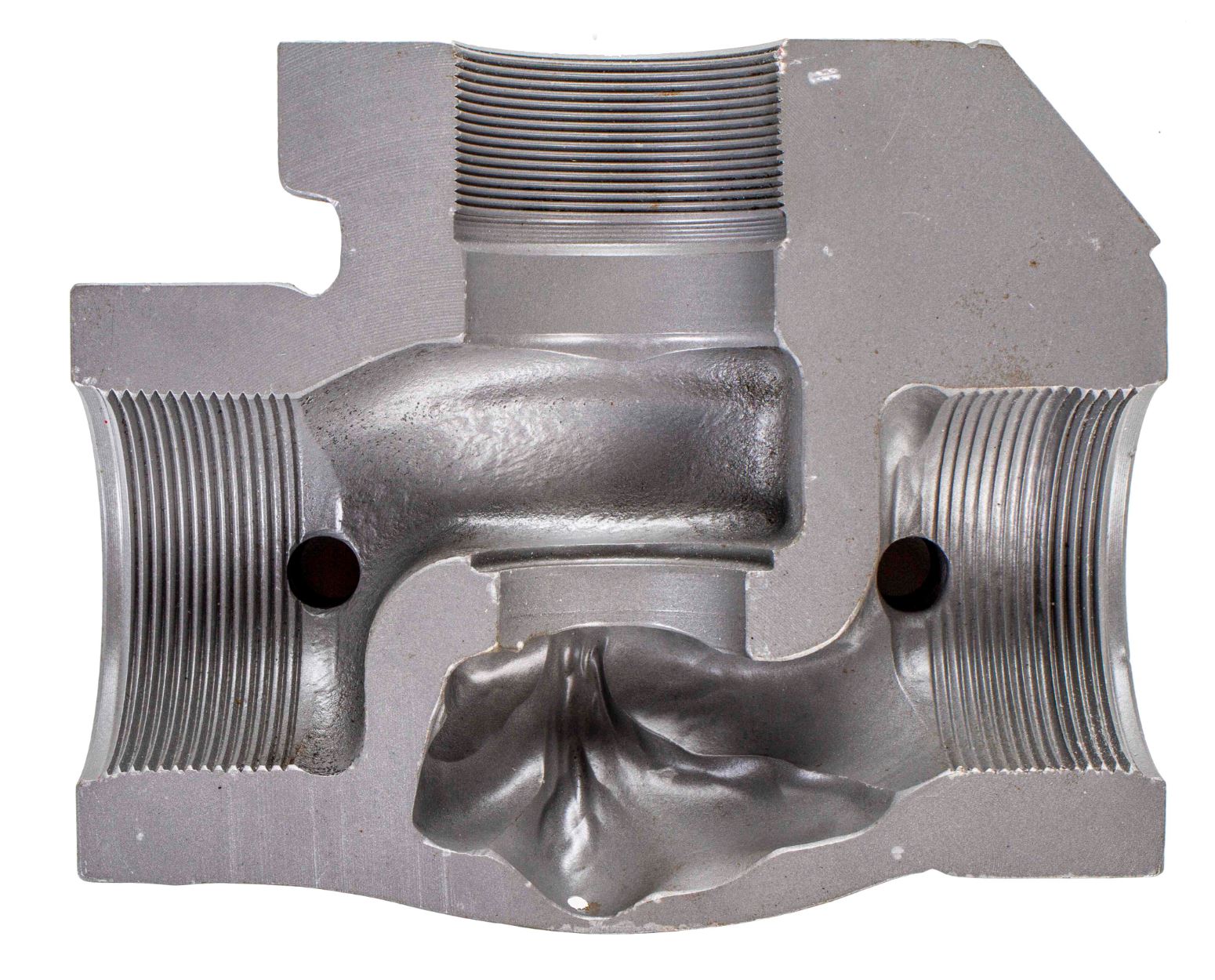

The valve below examine in the video is a stem-guided control valve experiencing a 320-pound pressure drop. Though it’s a 2000-pound body, it lasted less than a week in normal operation

As the flow came through the body, the sand quickly eroded the metal, eventually boring a hole through the bottom.

That’s an inch of solid steel being worn away from tiny particles of sand coming at high pressure!

Also, notice the wear change on the threads as the fluid left the body.

The choke nipple on the other side originally had a 3/8” bore and the damage the erosive fluid did here is obvious.

Damage like this is obviously coming from frack sand flowing through the valve.

3 Solutions for Sand Damage in Your Control Valves

Here are 3 dump valves that help you limit sand’s impact so you can maximize well production.

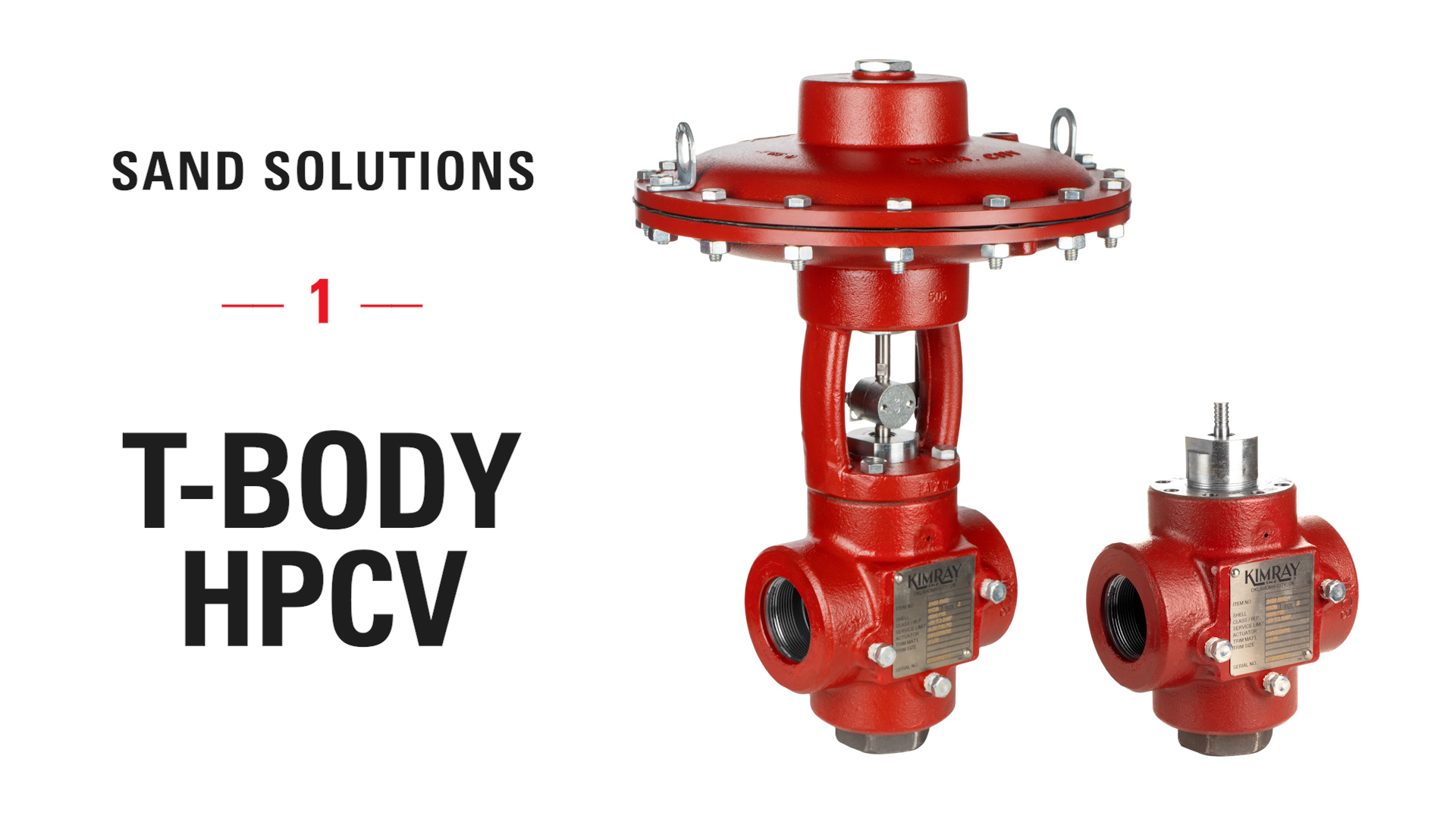

1. T-Body High Pressure Control Valve

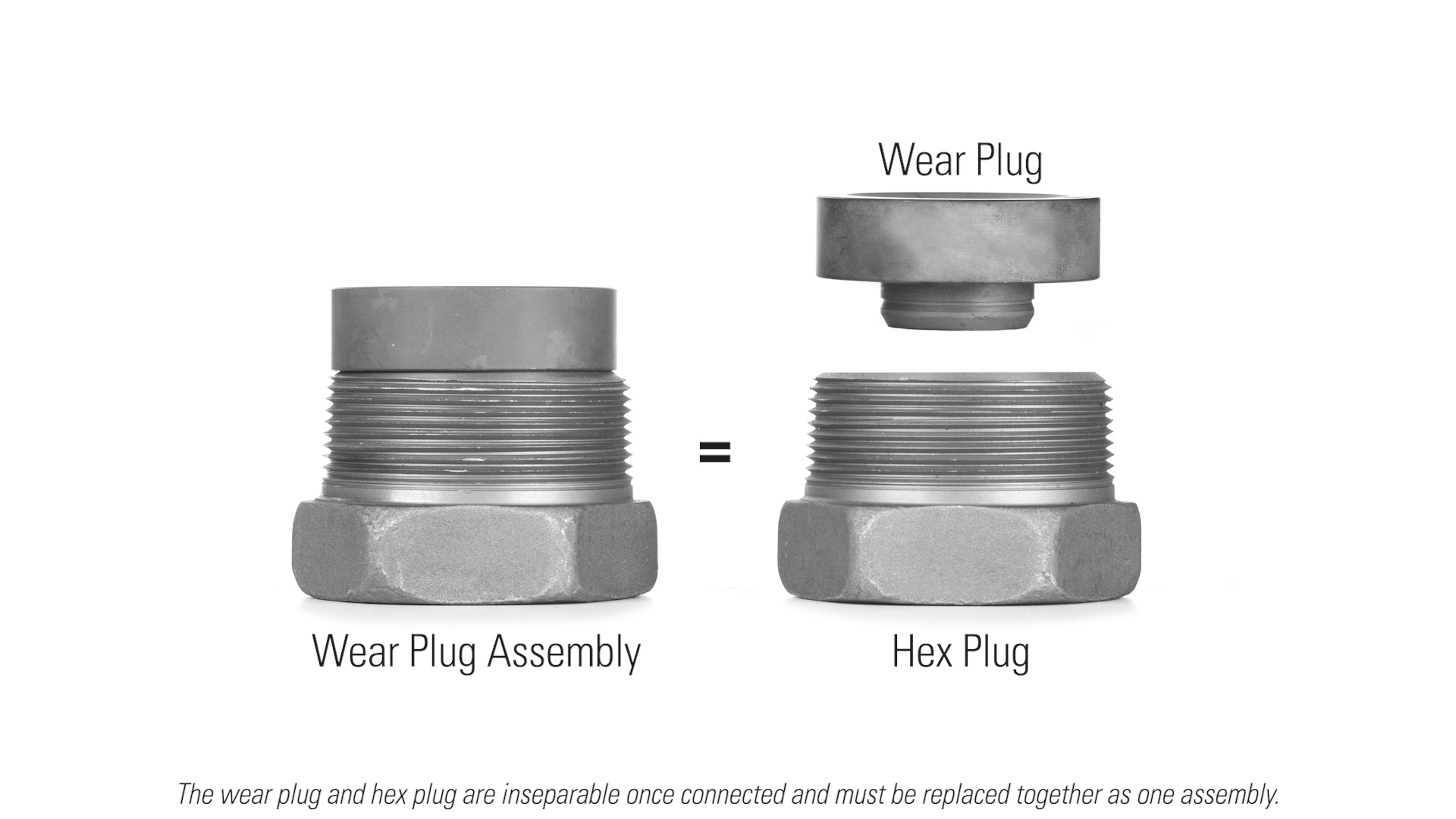

The T-Body High Pressure Control Valve is designed specifically for the erosive production conditions in today’s oilfield. The key feature of the T-Body is a hardened replaceable wear plug.

This assembly is designed to absorb the force of sand and other erosive materials that damage control valve bodies. It can be inspected and replaced without removing the valve from your pipeline. The T-Body provides long-lasting control of processes operating at over 500 PSI and allows you to minimize valve body replacements.

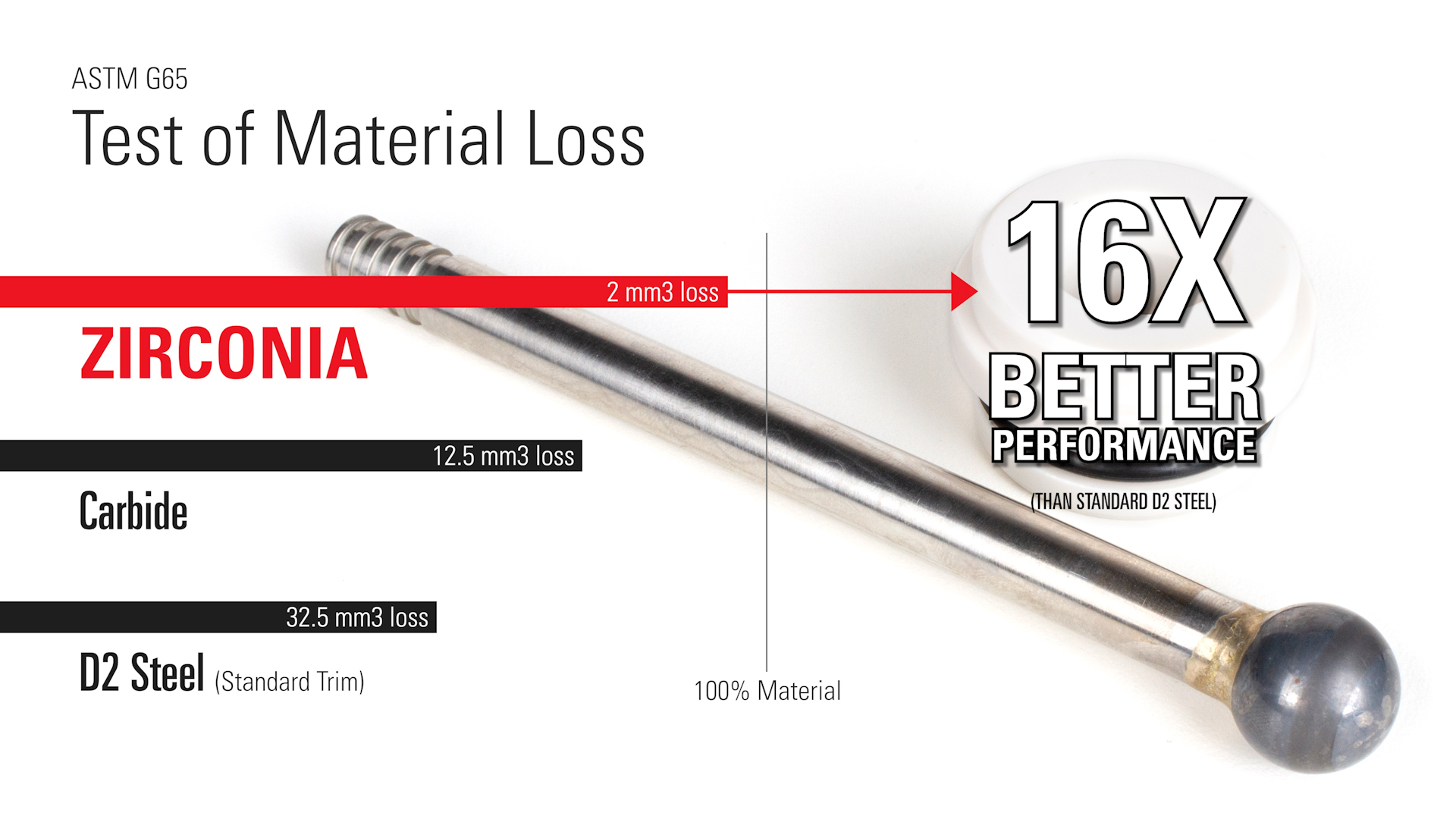

The valve body is not the only thing that takes a beating. The wear and tear on a valve trim and packing can cost thousands of dollars in repairs and replacements, not to mention downtime. Carbide and Zirconia trim are good options to consider if you’re experiencing highly erosive conditions. For more about these options, see our video on trim options for erosive production.

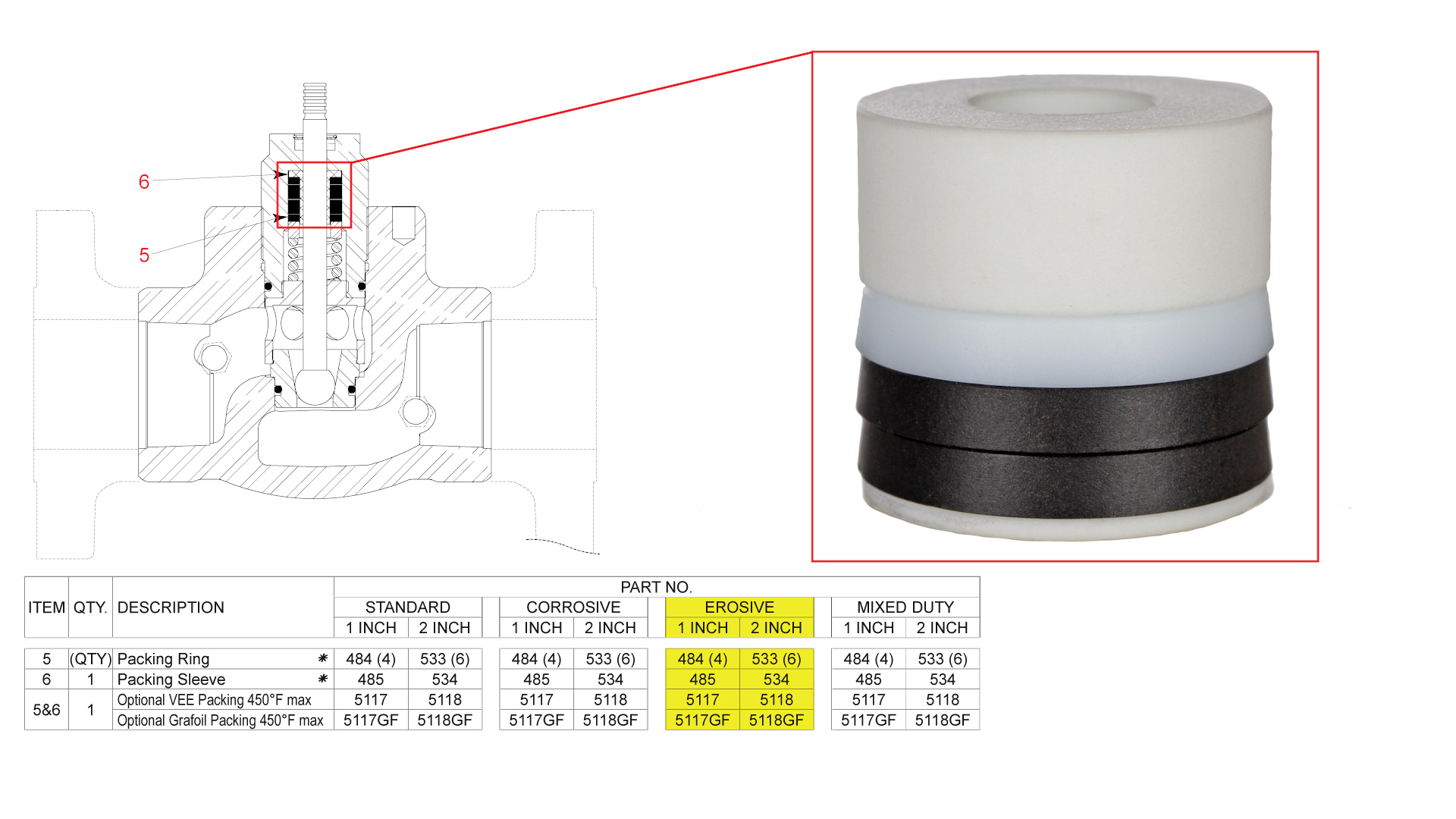

For valve packing in erosive conditions, we recommend VEE packing. This is a chevron-shaped packing made of robust Teflon or Grafoil material. It is designed to increase stability and sealing, even with increased load and higher temperatures.

2. Low-Pressure High Volume Valve

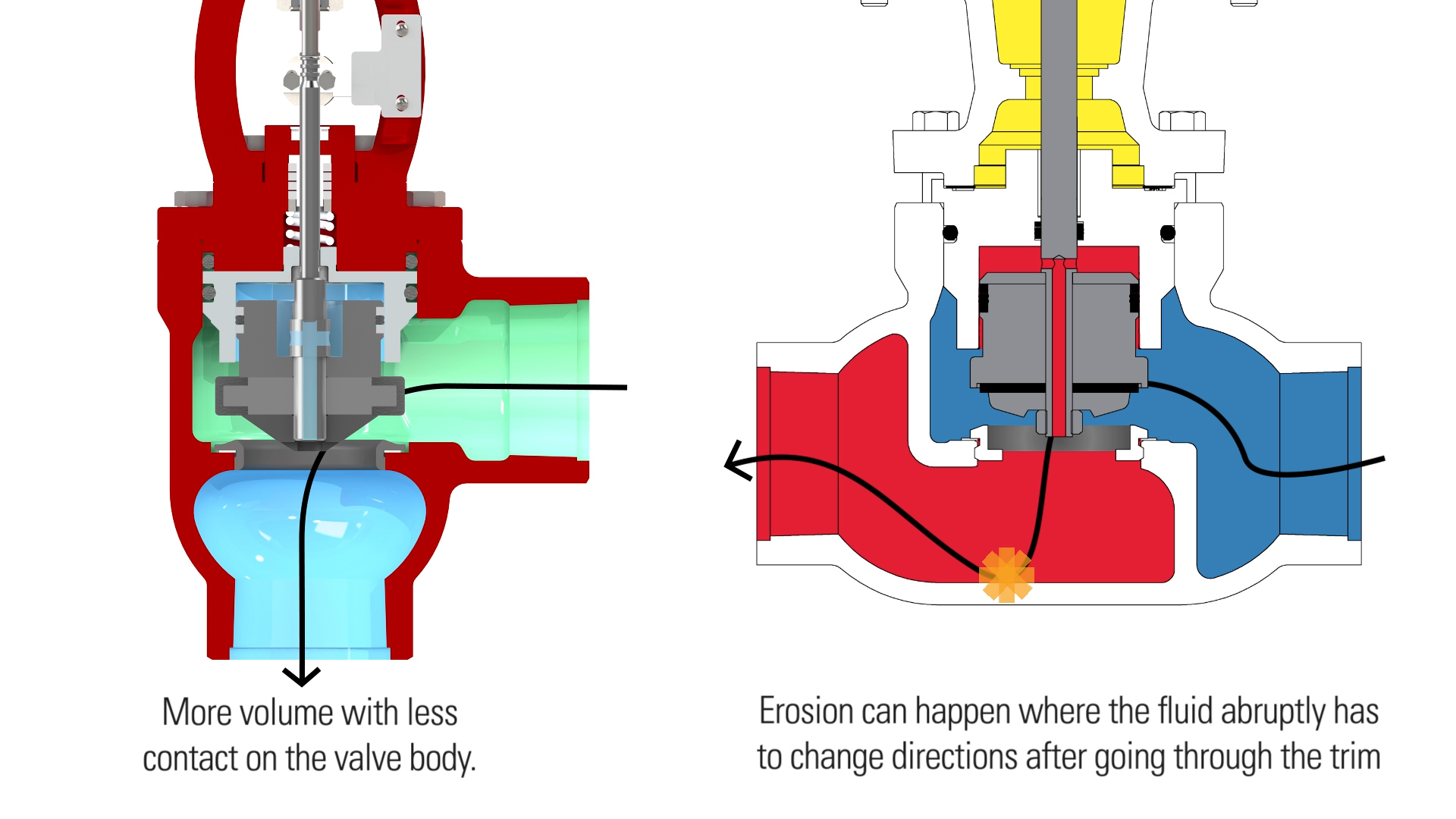

The Low Pressure High Volume Valve, or LPHV, provides long-lasting, robust control in erosive applications like flowback. The design of the LPHV creates a low-contact flow path for production fluid. This means that when the valve is open, more volume can flow through the valve with less contact—and damage—on the valve body and trim. The Low Pressure High Volume Valve is Ideal for liquid dump applications operating at less than 500 PSI on your separator or free water knockout.

In erosive conditions, be sure to specify the optional erosive internals for the LPHV, which include a D2 steel, removable seat and ratio plug.

3. PBT Liquid Dump Valve

Piston Balanced Throttling (PBT) Liquid Dump Valve pulls the seat, trim, and stem out of the flow path. This means that when the valve opens, the abrasive well fluid can dump while causing less damage to these internal parts. The PBT valve is a cost-effective, zero-emission option ideal for liquid dump applications operating at less than 500 PSI.

Piston Balanced Throttling (PBT) Liquid Dump Valve pulls the seat, trim, and stem out of the flow path. This means that when the valve opens, the abrasive well fluid can dump while causing less damage to these internal parts. The PBT valve is a cost-effective, zero-emission option ideal for liquid dump applications operating at less than 500 PSI.

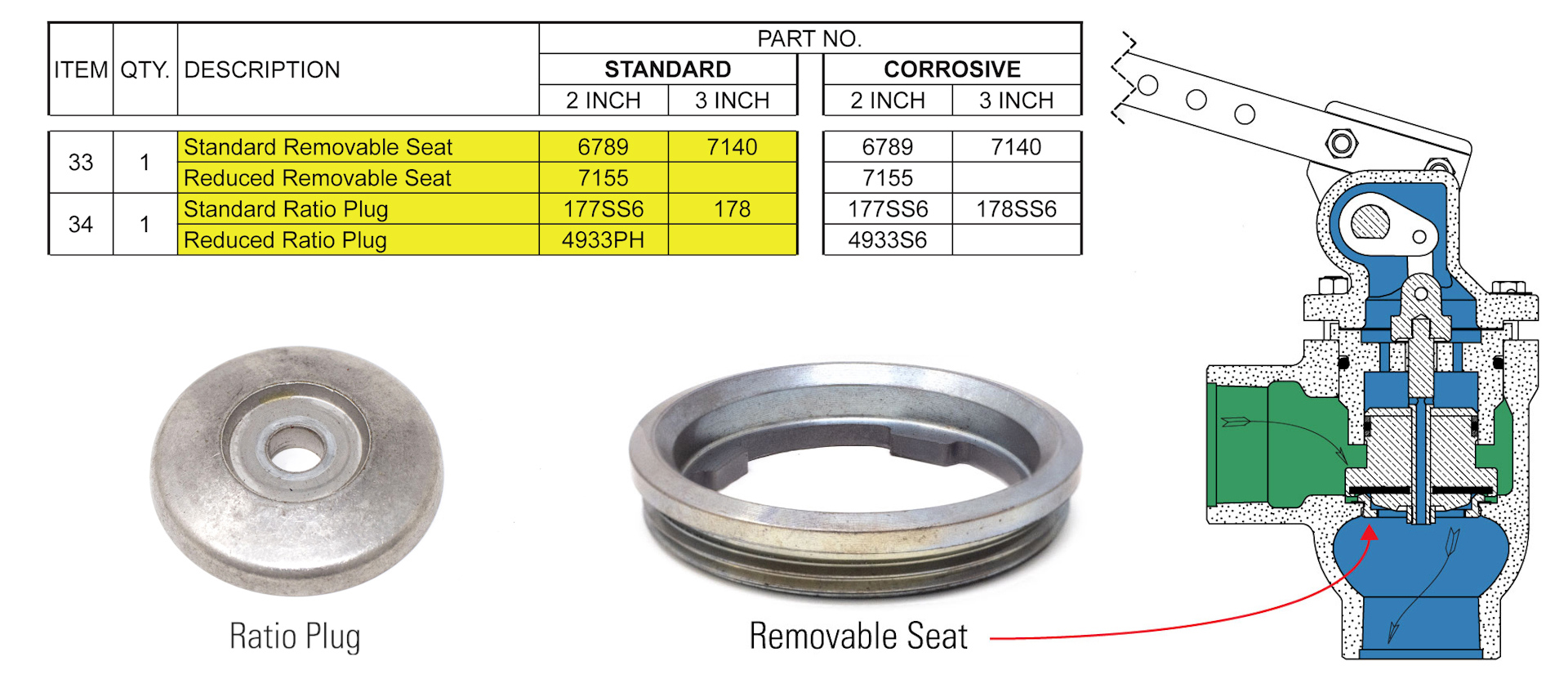

The PBT comes standard with a D2 steel, removable seat and a 17-4 PH ratio plug in the reduced port trim.

How to Repair the PBT Liquid Dump Valve

To speak with an expert about how to better manage the sand in your production fluid, contact your local Kimray store or authorized distributor.