Looking to reduce emissions at your well site?

One of the biggest challenges producers face is figuring out how to practically reduce or even eliminate methane emissions from their operations. As we've covered elsewhere, one simple way to do this in many liquid and gas applications is to use an outside pneumatic supply, such as liquid nitrogen.

Learn more about our outside supply partners Kathairos

Let’s take a look at how this can work in a High Pressure Control Valve package.

How Does a HPCV Package Work?

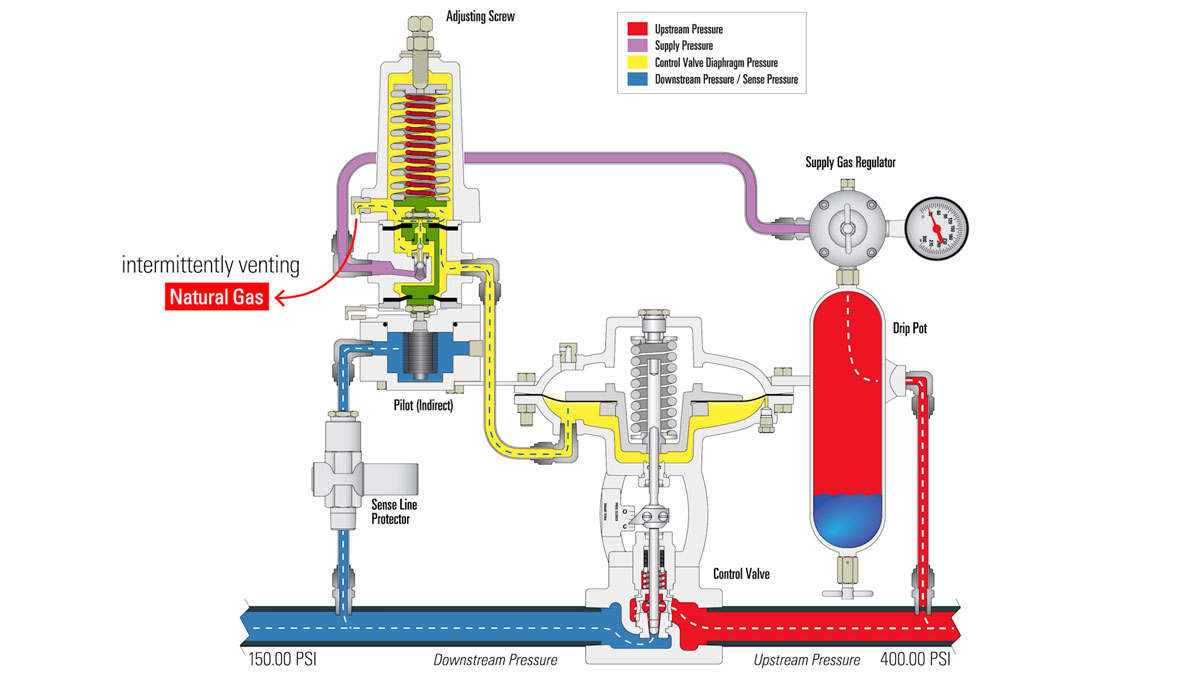

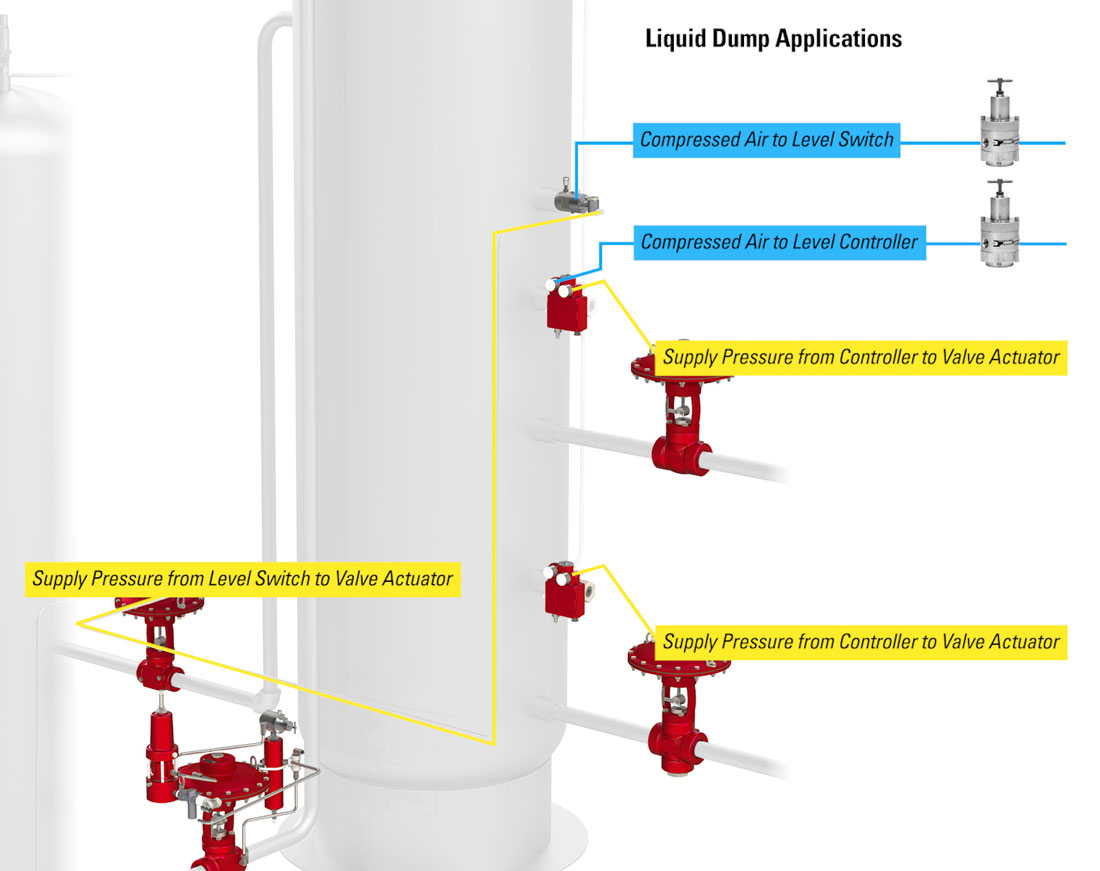

A High Pressure Control Valve package is a versatile solution used in many oil and gas applications, including gas back pressure and pressure reduction as well as liquid dump and artificial lift.

In a package like this one, a pressure pilot is used to supply instrument gas to the control valve, which allows it to open and close.

Where Do These Packages Emit?

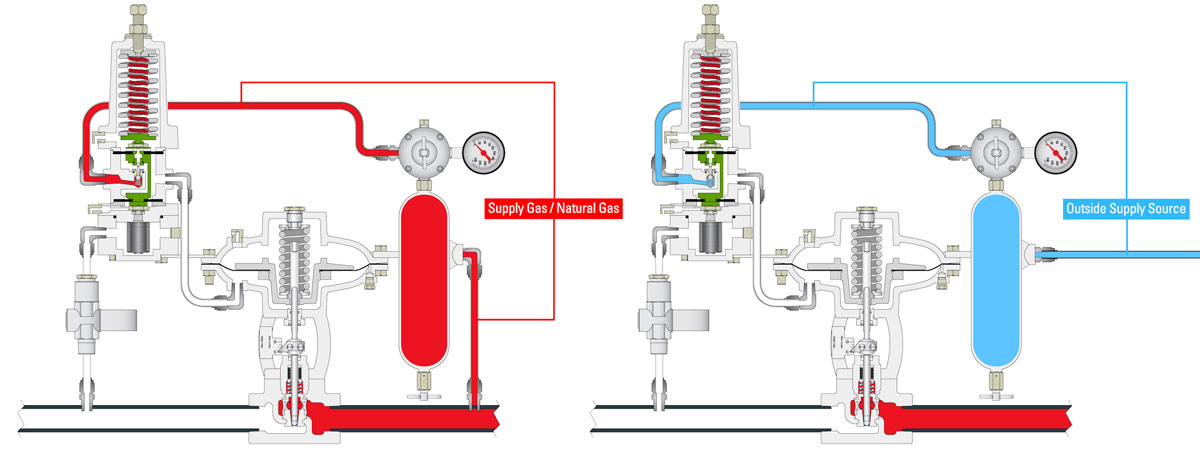

Traditionally, producers use natural gas as the supply for the pressure pilot.

This means that during normal operation, as the valve actuates and then returns to its original position, the pilot intermittently emits that gas into the atmosphere.

While it does not continuously emit, this is a process many energy producers are modifying to reduce their wellsite emissions.

How Can I Make the control valve Emission Free?

The good news is, it’s not as challenging as you would think to make your High Pressure Control Valve package emission free.

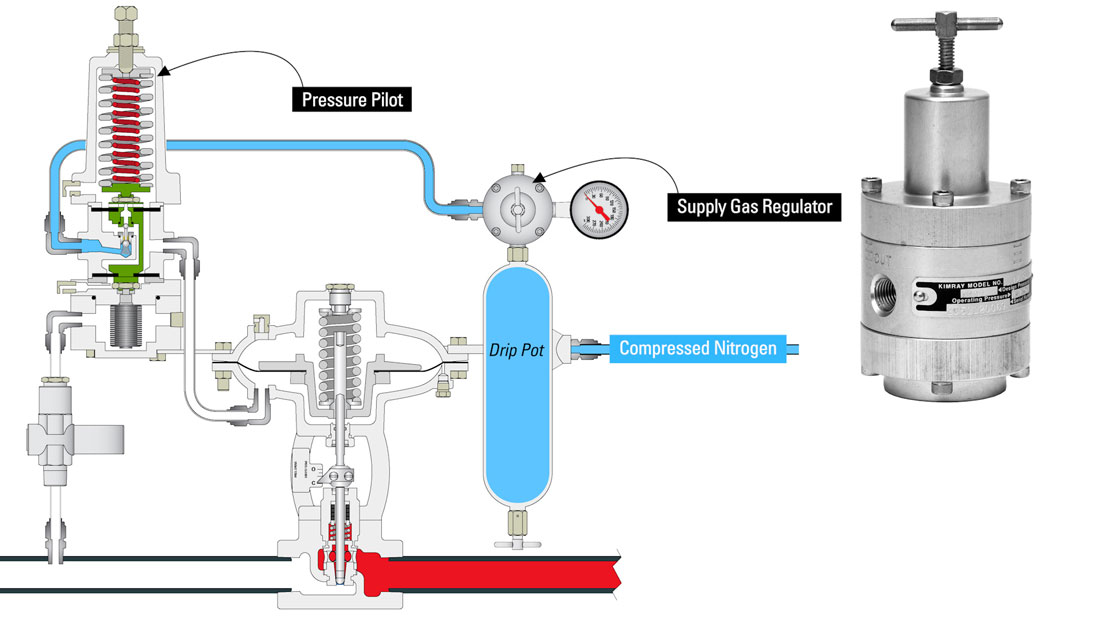

Here's how to do it: Rather than using supply gas from your production vessel for the pressure pilot, use an outside pneumatic supply source, like compressed liquid nitrogen.

Our partners Kathairos provide an ample supply of nitrogen while requiring no outside power source. Because nitrogen is an inert gas, it can be used to power pneumatic valves and controllers while releasing zero methane emissions when they vent.

Powered by thermodynamics, the nitrogen tanks have no moving parts and require no maintenance or external energy sources.

How to Convert a control valve to zero-emission operation

If the package you are using has been exposed to natural gas supply, you’ll first need to install repair kits, as switching from supply gas to nitrogen may cause the elastomers to shrink or crack.

When you’re ready to operate your valve with compressed nitrogen, you just need to source the supply to the pilot from the nitrogen line. You'll route the nitrogen to a supply gas regulator adjusted to the appropriate pressure as needed to actuate your valve.

In a back pressure or pressure reducing packages, this will then be tubed to the pressure pilot.

For liquid dump applications, it will be tubed to the pilot on the level controller or level switch.

Your Emissions Solutions Provider

We are dedicated to helping producers achieve their emissions targets. To explore more emission-free options—including electric solutions and compressed air—check out our full Emissions Solutions page.