After natural gas is produced from a well and initial separation has taken place, it will travel through a gas flow meter to measure the production.

These meters may be on a separation vessel monitoring production volumes, or they are used for custody transfer, where the gas is measured, and a midstream company takes ownership of it.

What is a Flow Meter Used For?

Producers use several types of flow meters depending on their gas volume and fluid properties. Each meter measures the flow rate, but the operation and methods of measuring are different.

Each one of these meters can be used in both upstream production and midstream transportation. In upstream production, they can be used to monitor individual well production, custody transfer at a sales meter or to meter the amount of chemicals being injected.

In the midstream, they can be used for inventory measurement, process control, fuel management and regulatory reporting.

Here are the four types of flow meter:

- Mass Flow Meter

- Velocity Meter

- Pressure Differential Meter

- Positive Displacement Meter

1. Mass Flow Meter

The first one we’ll talk about is a mass flow meter.

The mass flow rate is the amount of liquid that passes through a meter over a given unit of time. A mass flow meter measures this rate and is dependent on the density and velocity of the liquid and the size of the meter.

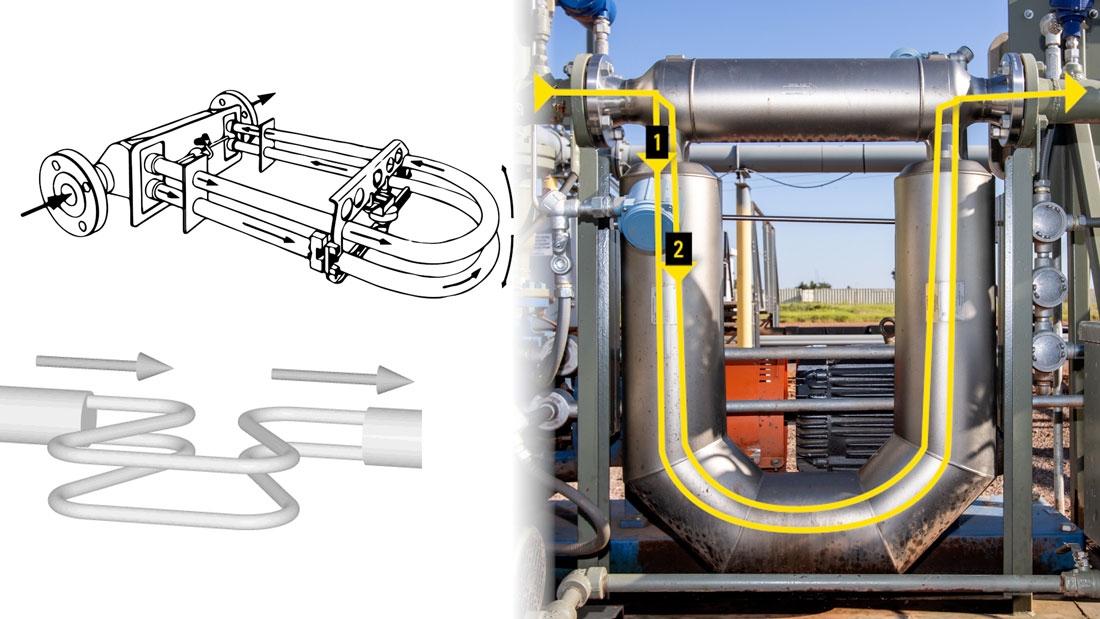

The Coriolis meter is the most common mass flow meter used in the oil and gas industry. Using motion mechanics, it splits the process fluid into two tubes oscillating in opposite directions. Voltage is generated by vibrations, sine waves are created, and the time delay in motion is proportional to the mass flow rate.

Coriolis meters are extremely accurate. They are also expensive, so they are not suitable for large flow volumes because larger meters are not cost effective to produce.

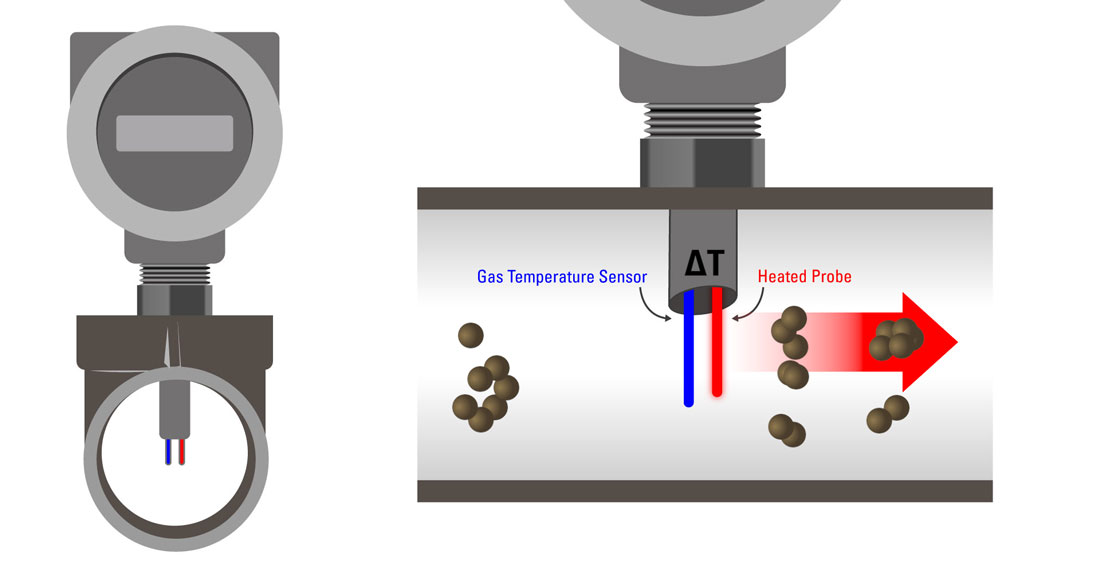

Another type of mass flow meter is a thermal mass flow meter. This meter measures the fluid volume based on the heat transfer or temperature change, from a heated element positioned in the flow stream. The more fluid that passes around it, the faster it cools, indicating greater flow volumes.

Thermal mass flow meters provide excellent accuracy and repeatability.

2. Velocity flow Meter

With a velocity meter, the velocity of the fluid passing through it determines the measurement.

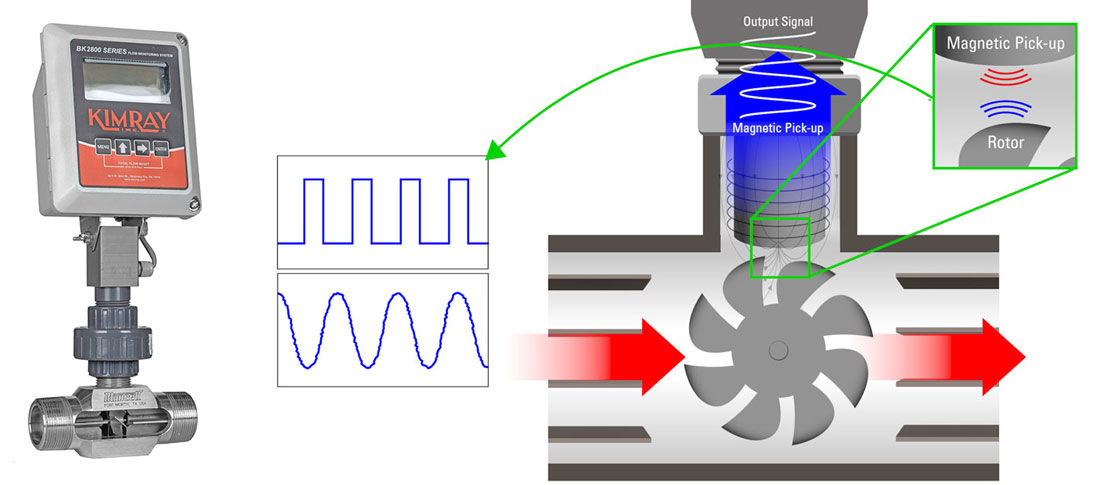

The most common velocity meter is a turbine flow meter, which calculates flow based on fluid flowing through a free-spinning rotor. Each revolution of the rotor is read by a magnetic pickup and corresponds to a specific volume of gas or liquid.

Because of the moving parts and operation, turbine meters are limited to single-phase fluids, such as dry gas or liquid. To compensate for varying applications, pressure and temperature, those variables must be imputed into the flow monitor to calculate accurate measurement.

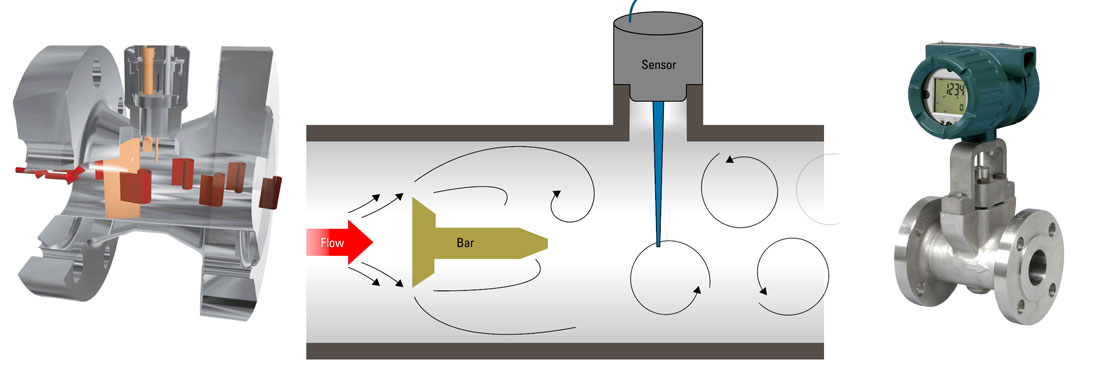

Vortex flow meters operate under the vortex shedding principle, where an oscillating vortex occurs when a fluid flowing past a bar positioned in the flow path generates a frequency that can be read by the meter. Because there are no moving parts, it is ideal for applications where low maintenance costs are important.

Ultrasonic flow meters measure the difference in pulses transit time that travels from a downstream transducer to the upstream sensor and vice versa. Ultrasonic meters are highly accurate but very expensive and require extra input for pressure and temperature.

3. Pressure Differential Meter

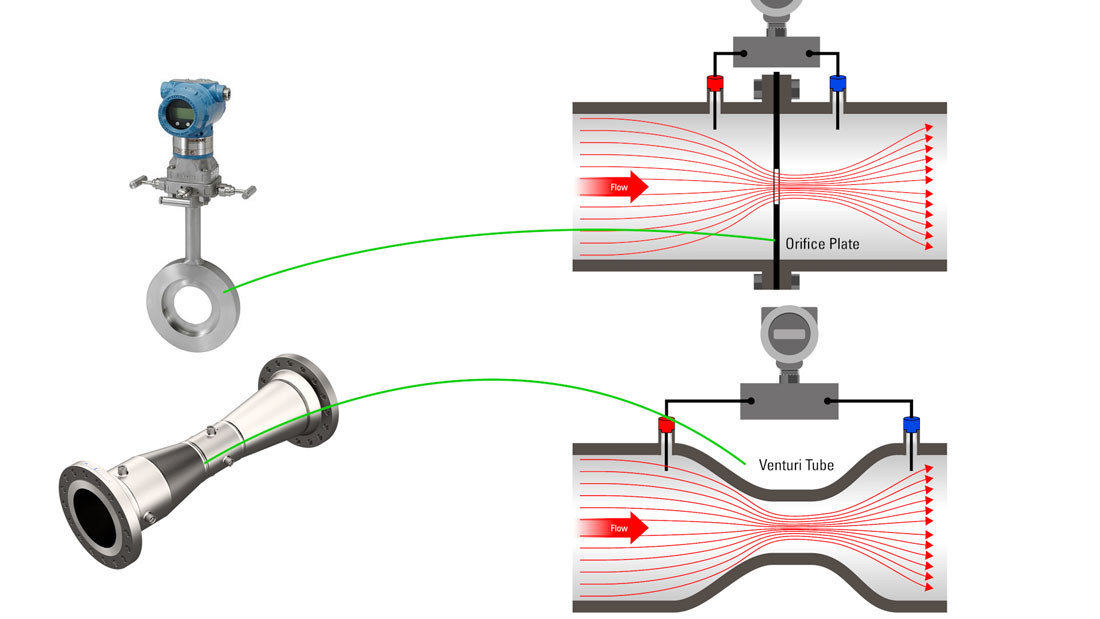

A pressure differential meter operates by measuring a pressure drop across a fixed obstruction inserted into the fluid flow path. Orifice plates and venturi tubes both operate off pressure differentials.

Both orifice plates and venturi tubes operate by restricting flow, which causes the pressure to drop. The pressure on the upstream and downstream sides of the meter is measured using pressure transducers.

The pressure differential that’s created allows flow monitor to determine the flow rate using Bernoulli’s Equation. Temperature and pressure must be considered for accurate measurements.

4. Positive Displacement Meter

Positive displacement meters use fluid to displace mechanical components to measure volumetric flow. Compensations for the operating temperatures and pressures are needed for accurate measurements.

The most common type of positive displacement meter is a diaphragm meter, which can be found outside of most houses to meter the natural gas usage for utility companies.

To speak with an expert about metering or any other upstream oil and gas application, contact our Product & Customer Support team.