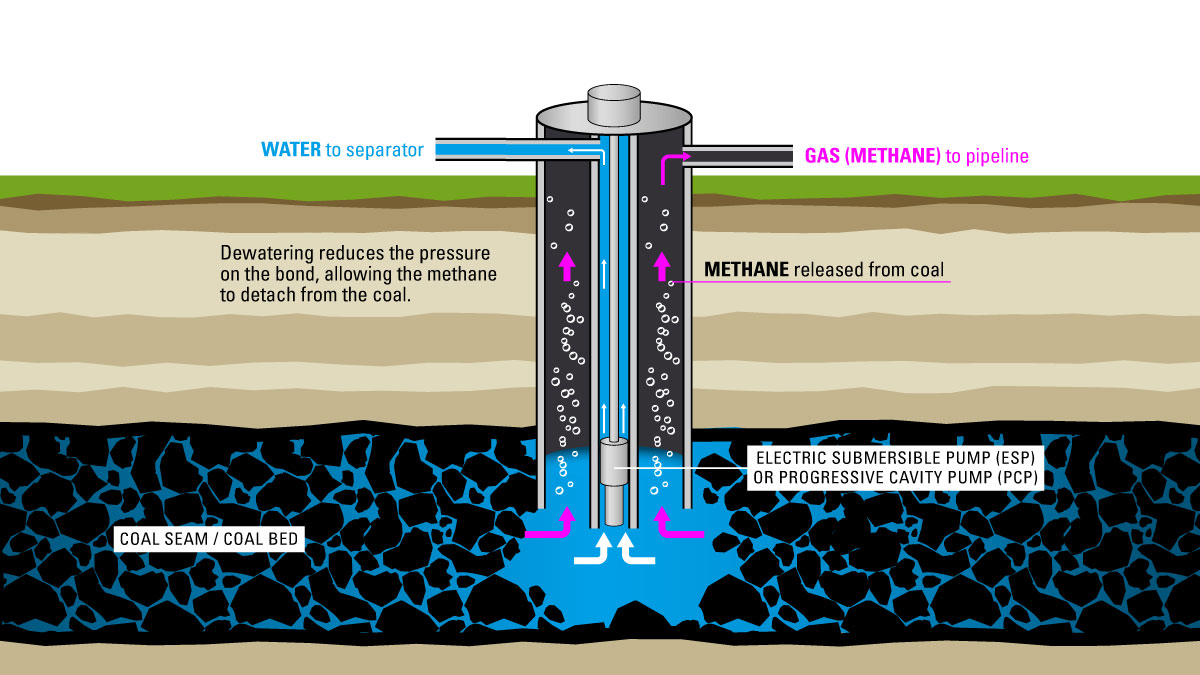

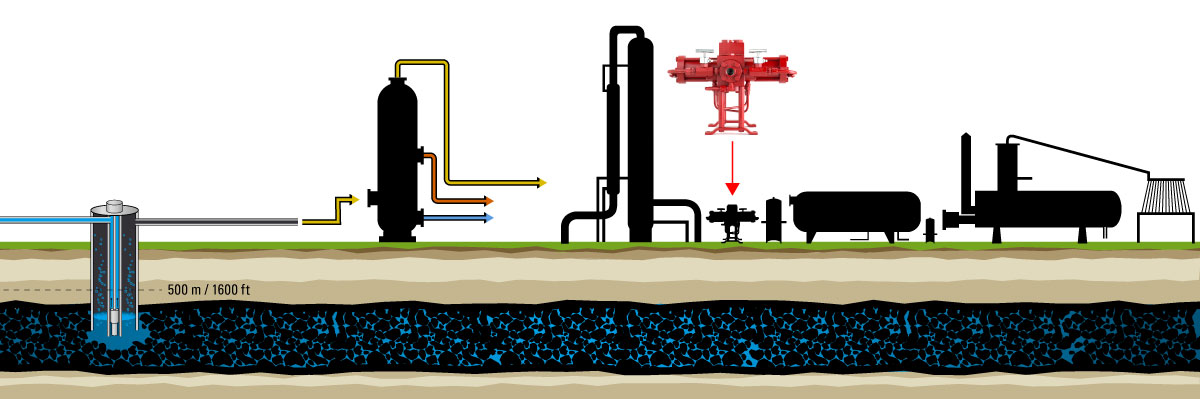

Coal Bed Methane production is a method of recovering gas stored in coal. Coal Bed Methane is quality gas that needs minimal processing.

This method, also referred to as Coal Seam Gas recovery, is very different than conventional gas production. Here’s how it works.

How is Coal Seam Gas Produced?

Methane gas is stored in coal by a process called adsorption. During adsorption, gas molecules are bound by weak electrical forces to solid organic coal molecules.

Once drilled, producing a coal seam gas well requires dewatering and separation.

gas well Dewatering

Due to the low gas pressure of these wells, producers use a downhole pump to take water off the well. For instance, they may use an electric submersible pump (ESP) or progressive cavity (PC) pump.

The pump sends the water up the tubing and to the producer’s surface equipment. This initial production is called dewatering. Recovery at this stage is mostly water.

Eventually, dewatering reduces the pressure on the bond, allowing the methane to detach from the coal and flow to the surface.

Control Equipment for Coal Bed Methane Production

Once the produced fluid is at the surface, it is sent through a two-phase separator to separate the gas from the water.

Producers use four primary control products for coal bed methane production:

- Trunnion Assembly

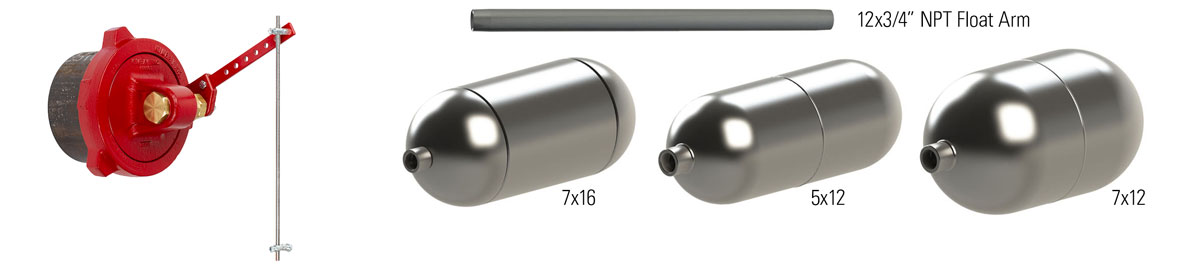

- Float Arm, and Float

- Lever Operated Piston Balanced Throttling Liquid Dump Valve

- Non-Vent Back Pressure Regulator

Trunnion Assembly / Float Arm & Float

A trunnion assembly is attached to the production vessel and connected to a float, which sits inside in the vessel and moves according to the fluid level. This movement opens and closes the Lever Operated Dump Valve, which is attached to a flow line.

Lever Operated Dump Valve

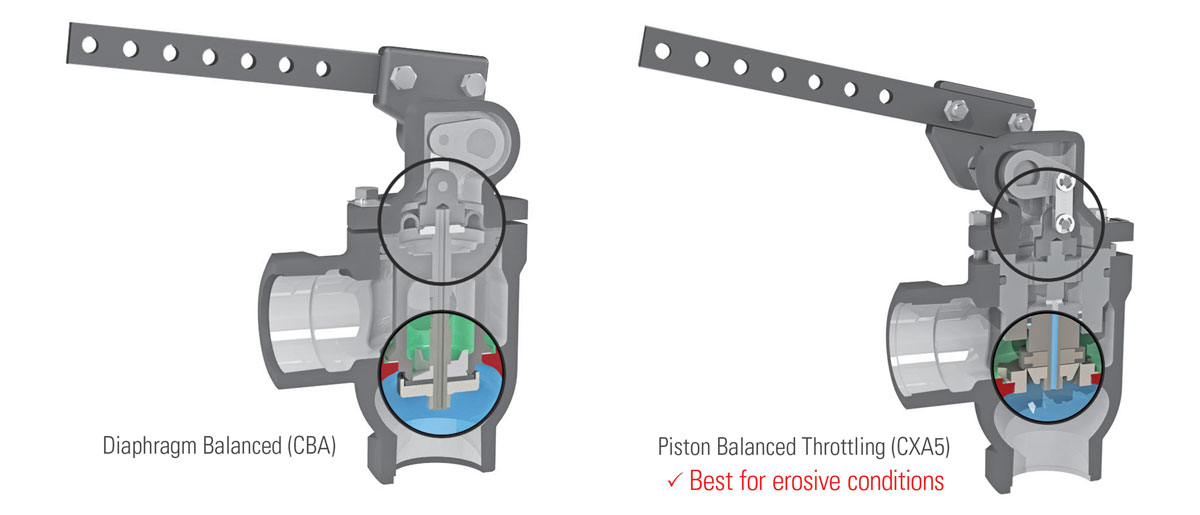

One of the challenges with Coal Bed Methane production is the coal fines and chips that work their way into the production fluid. When these contaminants get into tight spaces, they can cause erosion to your equipment.

The Kimray Lever Operated, Piston-Balanced Throttling Liquid Dump Valve, or PBT for short, is ideal for erosive conditions like exist in Coal Bed Methane because the equal percentage trim lifts out of the flow path when it opens, limiting contact with the process fluid.

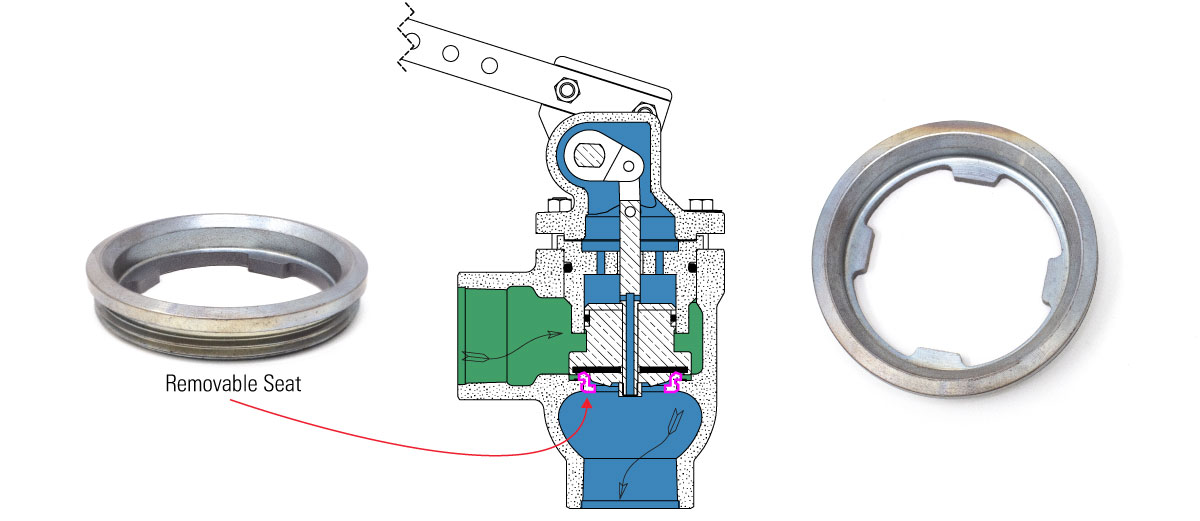

The PBT comes standard with a D2 steel removable seat for increased erosion resistance.

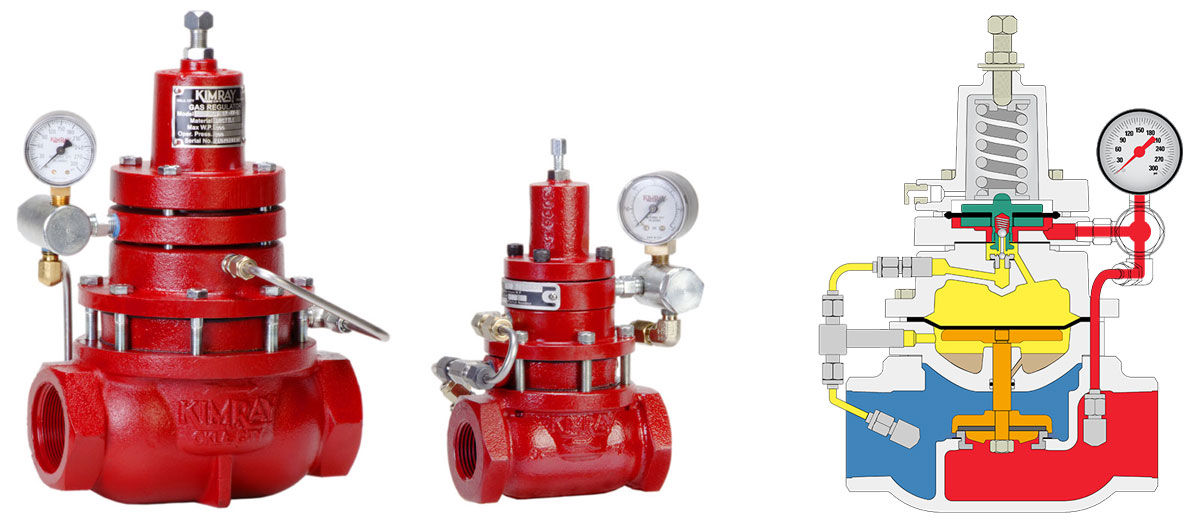

Non-Vent Back Pressure Regulator

Producers use a Non-Vent Back Pressure Regulator to hold pressure on separation vessels, so that when the dump valve opens it has the energy to move the water out of the vessel.

The regulator uses the upstream process gas to maintain its set point. Then, rather than venting this gas into the atmosphere, it redirects it back into the downstream production piping.

Gas Dehydration in Coal Bed Methane Production

By nature, the gas produced in Coal Bed Methane contains a good amount of moisture when first separated.

Once initial separation is complete, producers send it through a natural gas dehydration system to dry the gas.

To explore more what products Kimray offers to optimize your dehydration system, check out our Natural Gas Dehydration playlist.

HAVE MORE QUESTIONS?

Kimray has pioneered coal bed methane production processes with producers across the United States, China, India, and Australia.

To connect with a representative, reach out to your Kimray store or authorized distributor.