INTRODUCTION

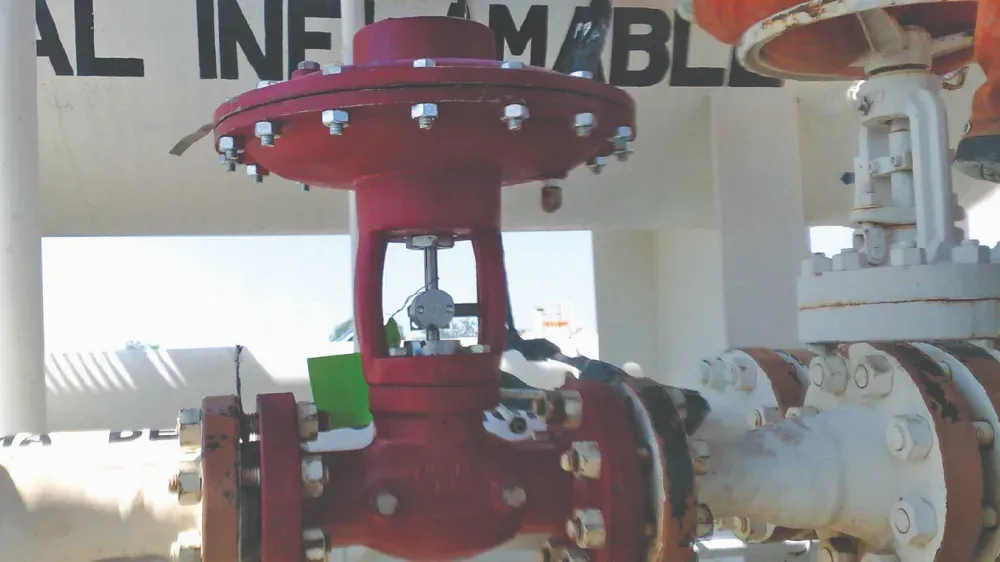

The high content of abrasive liquids flowing through the control elements of the separation stations of Activo Integral Burgos

Reynosa causes a very short trim life.

Under these conditions, a suggestion was made to personnel of “Pemex Exploración y Producción” to carry out the installation of Kimray level control valves for liquids with their trim made from materials designed to resist friction of abrasive elements and also to decrease the frequency of maintenance.

To reach this objective, the proper sizing of the valves to be tested was made and the proper materials were selected.

Production Details

- Field Fundadores 1 Reynosa, Tamaulipas

- Pressure of Separators: 800 psig

- Atmospheric Discharge Pressure

- Regulation Pressure: 15 psig

- Flow: 370 gpm

CALCULATIONS

With the process data and using Kimray’s Sizing Calculator we get the process Cv = 3.4. Ideally, a control valve must work at 50% of its capacity. For this reason, it is necessary to multiply the process Cv by 2 and to search a valve with a similar Cv. In quick opening, it is not necessary to work at 50%, so it is possible to work with a valve with a higher capacity

MATERIALS

The tables show the hardness of carbide compared to stainless (303, 316 and 174 PH) and standard (Steel D2) materials. Although zirconia is much harder than carbide because it is a ceramic material, carbide is protected when working at low speed zones with a quick opening seat.

RESULTS

Observed in the Control Valve

Sizing the valve correctly, selecting a quick opening seat and choosing tungsten carbide extend the life of valve trim. The quick-opening flow characteristic makes possible to work in zones in lower speed zones. In short, it is possible to solve abrasion problems only by thoroughly analyzing the application and by making the proper selection of control equipment.

Observed by the Maintenance Personnel in the Gen II Level Controller

- Easy calibration

- Change of connection from right hand to left hand in the same controller

- The adjustment point is not lost

PRODUCT

Summary of Installation: E2HPMV / 2”-600 RF / ¾” IV Carbide / Viton Elastomers