1. What is the Purpose of a postioner in a control valve?

A positioner for a control valve is used to adjust a valve’s position based on a desired set point for a process variable, whether it be pressure, temperature, or flow.

Below, we’ll talk about why you might want to use them, how the three main types of positioners work, and the options that Kimray provides.

2. How does a positioner work?

Producers typically install valve positioners on the yolk or top casing of a pneumatic actuator for linear control valves. On rotary control valves, the valve positioner is installed in line with the valve and actuator stems on top of the actuator or on the side of the actuator. Installation depends on what type of actuator one uses.

Affixing the positioner to the actuators allows the positioner to measure the stem travel (linear valves) or degree of rotation (rotary valves). This also changes the position of the valve as required based on the input signal from the instrument controller.

When the process variable differs from the desired set point, the instrument controller sends an electrical or pneumatic signal to the positioner. This varies its pneumatic output to the actuator to move the valve open or closed accordingly. This occurs until the process variable reaches the desired set point.

3. How many types of positioners are there?

There are 3 primary types of positioners:

- Pneumatic Valve Positioner

- Electro-Pneumatic (EP) Valve Positioner

- Digital Valve Positioner

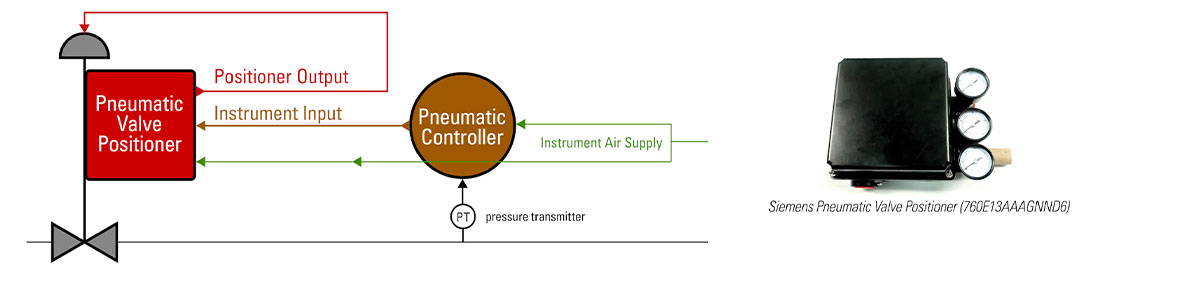

4. What is a Pneumatic Valve Positioner?

A Pneumatic Valve Positioner receives a pneumatic signal (typically 3-15 or 6-30 psi) from a controller. It then supplies the valve actuator with the correct air pressure to provide an accurate valve stem or shaft position proportional to the pneumatic input signal.

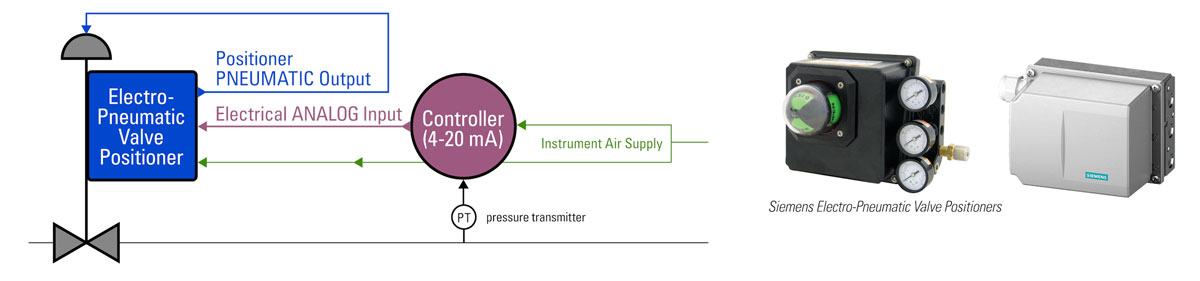

5. What is an eP Positioner?

An Electro-Pneumatic Positioner, sometimes abbreviated "EP Positioner," receives an electric signal (typically 4-20mA or 0-10 VDC) from a controller. It then sends a corresponding pneumatic signal to a pneumatic valve actuator.

EP Valve Positioners may also be referred to as “analog positioners.” This is because the electrical input to the positioner is an analog signal.

Since many processing units use electronics with a 4-20 mA DC signal to modulate control valves, the positioner must convert the electronic current signal into a pneumatic pressure signal.

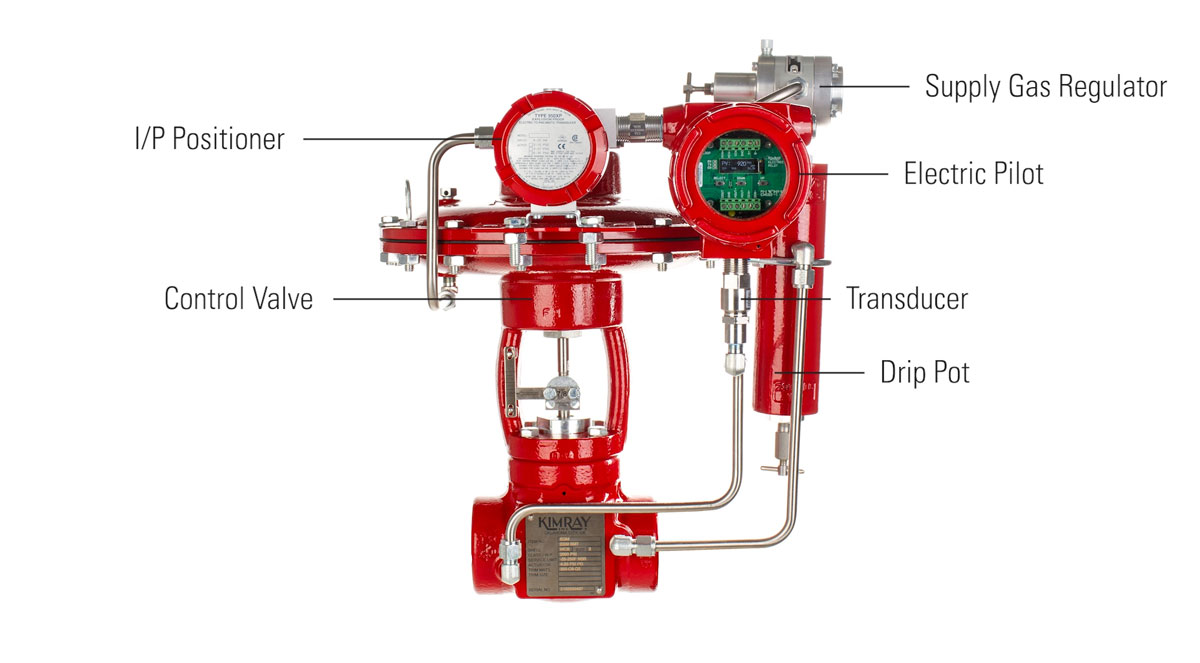

This is also known as an I/P positioner or transducer, such as Kimray’s YAK2.

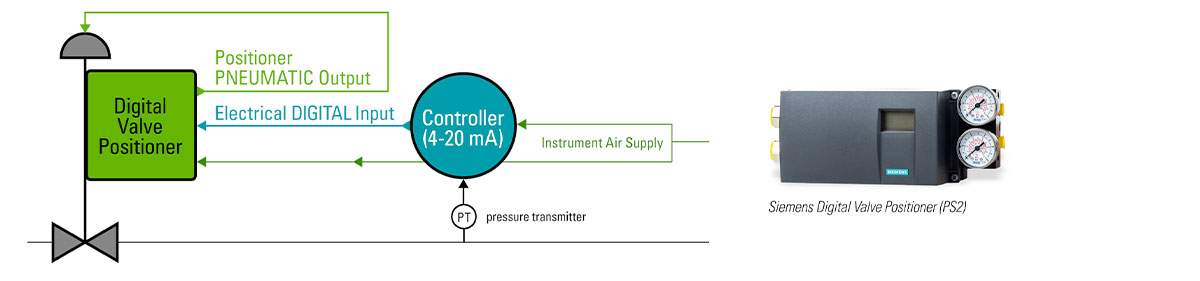

6. What is a Digital Valve Positioner?

A Digital Valve Positioner also receives an electric signal from a controller (typically 4-20mA, HART, PROFIBUS, or Foundation Fieldbus), but it’s digital as opposed to analog. It then sends a corresponding pneumatic signal to a pneumatic valve actuator.

It also differs from an EP Positioner because it uses a microprocessor to convert the control signal and perform the position control rather than a mechanical beam, cam and flapper assembly found in an EP.

This electrical input allows more advanced capabilities for the user. These digital “smart positioners” also collect data to automatically alert users about valve performance, diagnostics and maintenance.

Siemens PS2

The Siemens PS2 is one example of a digital valve positioner. The PS2 can remotely monitor and control any pneumatic valve. We offer it with many different communication protocols and enclosure options to meet customer needs.

The PS2 may be operated manually or electronically. It’s simple to program, with only three buttons and a two-line display and it can be calibrated in minutes.

The PS2 also features low air consumption compared to the industry average and only use air when required so you'll quickly reduce costs incurred by air generation, maintenance and material.

Electric Valve Controller

One Kimray-designed solution that combines the positioning capabilities we’ve talked about in this video and more is the Electric Valve Controller.

The Electric Valve Controller is a compact, easy-to-use, versatile solution for oil and gas automation, including remote monitoring and control of your production.

You can use the Electric Valve Controller for back pressure control, suction control, pressure differential or hi-low gap control all through a simple 3-button interface.

For further information about how a control valve positioner can improve your operation, contact your local Kimray store or authorized distributor.