The Kimray High Pressure Control Valve is one of the most versatile valves on the market. It can be used in numerous applications to provide control of oil and gas production processes. It can be used as a:

- Gas regulator

- Dump valve (with liquid level controller or level switch)

- Pressure reducing valve

- Back pressure valve

In this guide we’ll walk through some specific types and applications for this valve, including:

- Stem-Guided “Unbalanced” Valves vs. Cage-Guided “Balanced” Valves

- Crack Pressure

- Back Pressure vs. Pressure Reducing Applications

- Flanged Connections

- Types of Valve Trim Action

- Types of Valve Trim Materials

- Fail Closed vs. Fail Open Valves

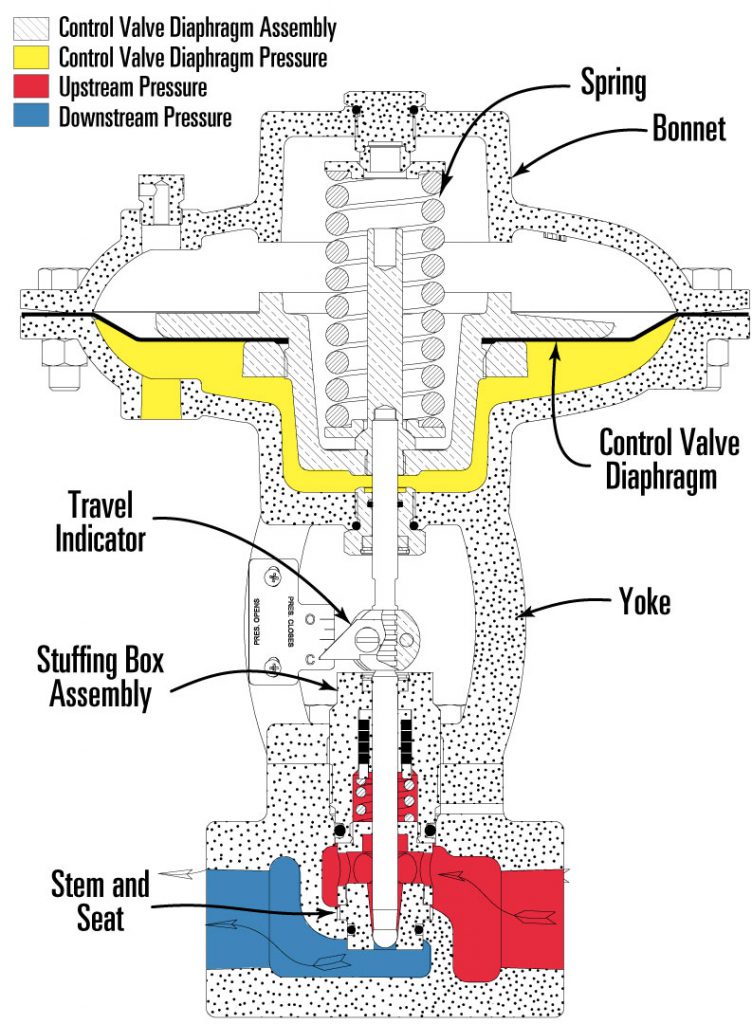

Two primary categories of high pressure control valves are stem-guided, which are “unbalanced,” and cage-guided, which are “balanced.” Let’s look at some of the differences.

Stem-Guided “Unbalanced” High Pressure Control Valves

Stem-guided valves are “unbalanced.” What does that mean?

In the figure below, red represents upstream pressure and blue represents downstream pressure.

All the upstream pressure is coming over the seat and rests on the ball. In this case, you have pressure pushing down on the ball, creating force and making it unbalanced.

With larger pressure drops, the valve can have trouble opening up against that downward force. This is especially true with larger trim sizes like 3/4" and 1" valve trim.

- Connection sizes: 1" – 2"

- Trim sizes: 1/8" – 1"

- Advantage: Stem-guided valves provide very tight control, which is ideal in low flow, high pressure drop, and gas regulation applications. (Example: in the 1" stem-guided valve you can get down to 1/8" trim.)

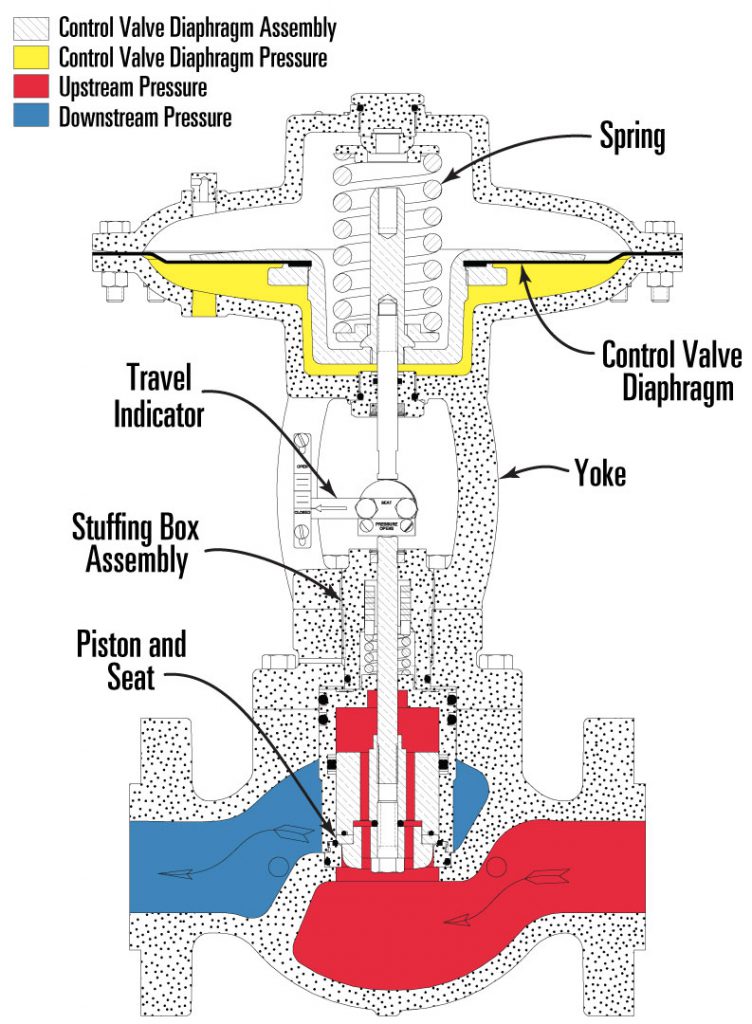

Cage-Guided “Balanced” High Pressure Control Valves

Cage-guided valves are balanced. What does that mean?

In the figure below, you can see two communication holes taking upstream pressure and putting it on top of the piston as well as on bottom.

Those two pressures cancel out each other, making the valve “balanced.”

This means whether there is a 1,000 PSI pressure drop or a 10 PSI pressure drop, it will still take the same amount of supply signal to open and close the valve.

Another difference between cage-guided and stem-guided valves is the available sizes. We offer 2" – 10" cage-guided valves, along with a full port and a reduced port trim option for each connection size.

- Connection sizes: 2"-10"

- Trim sizes: Full port or Reduced port

- Advantage: Cage-guided valves can flow a lot of volume quickly because of the size of the valves can be larger. This is ideal for applications with high pressure drops and large flow rates.

Watch Cage Guided High Pressure Control Valve Repair Video

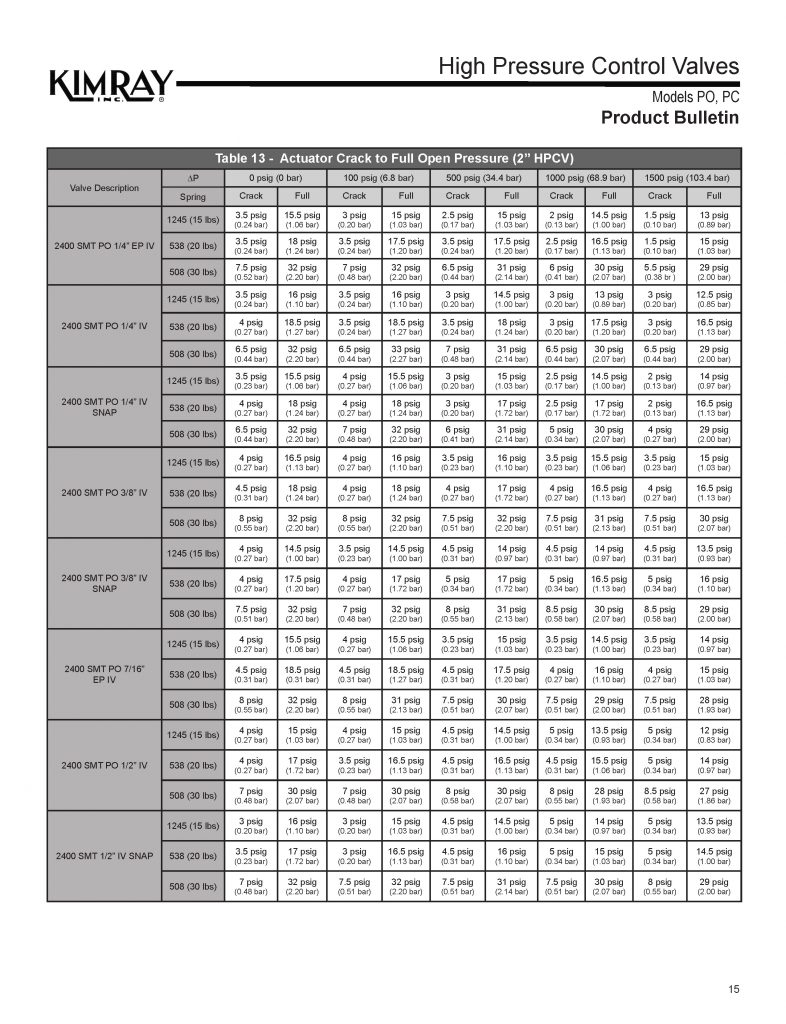

Crack Pressure Chart

Once you’ve chosen your stem-guided or cage-guided valve, you may want to know how much supply pressure your valve will require to open.

It’s safe to assume that 30 PSI is going to actuate any of these valves under any conditions. So we recommend having 30 PSI available.

However, for some of the smaller trim sizes and lower working pressures you don’t necessarily need 30 PSI to actuate.

If you don’t have 30 PSI and you want to know exactly how much supply pressure you need for your valve, you can reference our Crack Pressure Chart.

On this chart you can see all of our stem-guided valves. Here you can identify the different trim sizes and then also a pressure drop.

This shows you at what supply pressure it will crack—meaning start to open—and then at what pressure it will fully open.

Note that there are different trim sizes and springs.

Also included are the operating pressures, so you can see exactly how much supply pressure will be required in the application that your valve is going into.

Types of Valve Trim Action: Snap, Nominal, Equal Percentage

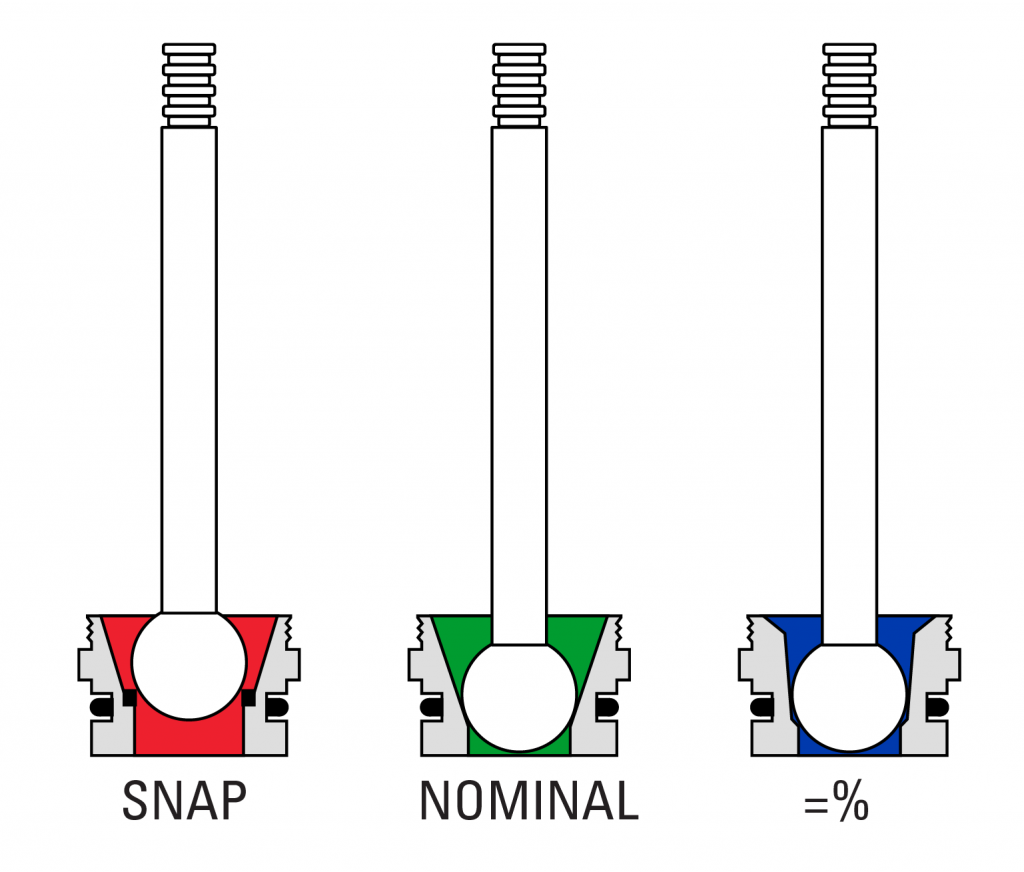

In our stem-guided valves, there are three different valve trim types—snap, nominal, and equal percentage.

Each valve trim type opens at a different rate.

The chart above shows the percentage of flow and the percentage of stem travel.

Snap Trim

The red line represents snap trim, which opens very quickly. At 50% open, it’s almost 100% of flow.

Primary applications for snap trim include liquid dump in erosive conditions and liquid dump when you’re metering liquids.

Nominal Trim

The green line represents nominal trim, which opens a little slower, and doesn’t actually hit 100% open until you get to about ninety percent of the stem travel.

Nominal valve trim is typically used for dump valve applications.

Equal Percentage

The blue line represents equal percentage trim, which opens very slowly. It doesn’t reach 100% of flow until it’s at 100% stem travel.

Equal percentage trim is used for precise gas regulation. EP trim can also be used for liquid dumps or in applications where a smaller CV is required.

Types of Valve Trim Materials: D2 Steel, Carbide, and Zirconia

Depending on your application, you may need different materials for your high pressure control valve trim other than our standard.

D2 Steel Valve Trim

D2 steel is our standard valve trim material. It’s good for average conditions with little sand or erosion.

Carbide Valve Trim

If you’re battling sandy or erosive conditions, you may want to use our carbide trim. Carbide is 2.5x harder than D2 steel trim and has performed well in material loss tests.

Zirconia Valve Trim

Zirconia is a hard ceramic we recommend for valve trim in extremely abrasive conditions. In a test of material loss, Zirconia trim performed 16x better than standard D2 steel trim.

Elastomers

Elastomers are important sealers for control valve internals. Kimray offers several different types of elastomers depending on your application. Download our guide to elastomers to see which elastomers work for differing temperatures and conditions.

Some of these options include:

- Buna— standard elastomer

- HSN—a good option if H2S is present in your flow

- Aflas/Viton—the most robust elastomers you can use

Stuffing Box Assembly

Inside the valve body there’s a stuffing box assembly. Here you can see all the internals, The stuffing box will hold the stem the packing and the cage together.

The packing can come in two different options:

- standard packing

- chevron packing (Vee packing)

The packing seals around the stem and keeps the pressure and fluid or gas from escaping from around the stem. It’s called “live-load packing.” This means that there’s a spring energizing the packing and keeping pressure on it so it’s holding tight against the stem.

The chevron packing option works a little bit better and longer and has a higher working temperature than our standard option.

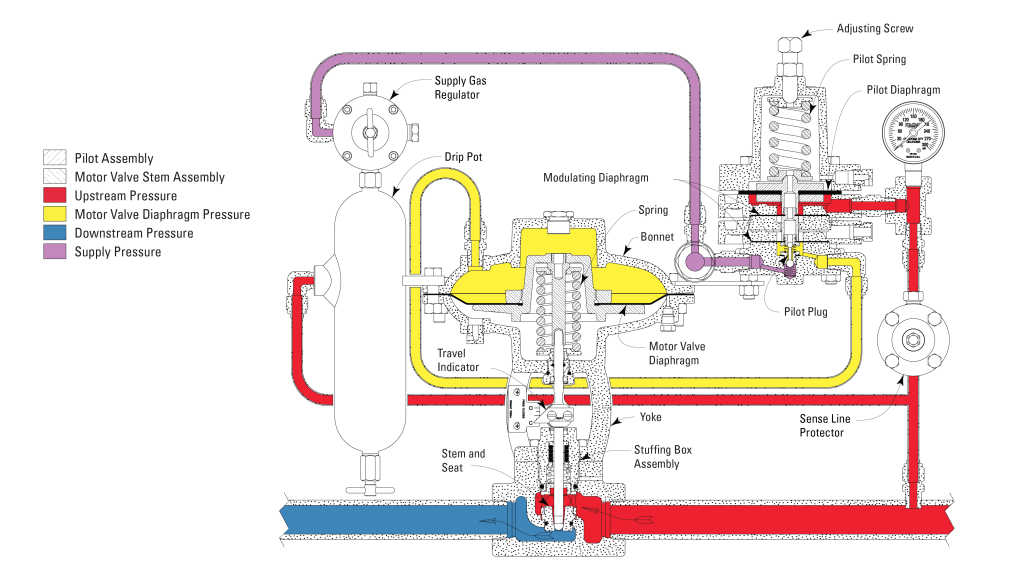

Back Pressure Regulator Package

A high pressure control valve alone won’t do anything. It needs a few supporting products to make it function.

To create a back pressure regulator package, you can begin with a stem-guided high pressure control valve and tube up a pilot, drip pot, and supply gas regulator.

The pilot monitors the upstream pressure, and then makes adjustments to the valve to regulate that pressure. If the pressure overcomes the spring in the pilot, the pilot will tell the valve to come open to relieve that pressure to get back down to your set point.

The drip pot just takes supply gas off the upstream of valve and knocks out liquids

The supply gas regulator regulates that down to 30 psi for the pilot.

Fail Open vs. Fail Closed

All of our back pressure packages come fail open.

With back pressure you’re concerned about what’s upstream of the valve, so in case of a failure scenario, the valve will open to relieve that pressure, saving whatever equipment is upstream of the valve.

All of our pressure reducing packages come fail closed.

For pressure reducing valves you are concerned about what’s downstream of the valve. So if something were to fail you want the valve to fail closed. This will save the equipment downstream of that valve.

From time to time you may need to switch the fail position of your valve.

For example: let’s say you have a pressure reducing package and you’re wanting to use it in a back pressure application. This means you need to change the fail position of the valve.

The valve’s topworks are field-reversible. Simply take the topworks apart, flip the spring and diaphragm assembly 180 degrees, and then put the top back on. This will change the fail position of the valve. This simple conversion can save you from having to purchase a completely new valve.

On-Site Training

We hope you found this guide helpful!

If you would like to request in-person training over high pressure control valves or any other Kimray product, contact your local Kimray store or authorized distributor.